Craftsman 21833 Support Question

Find answers below for this question about Craftsman 21833 - Professional Contractor Table Saw.Need a Craftsman 21833 manual? We have 1 online manual for this item!

Question posted by emcrvr7 on November 25th, 2012

Elevation Shaft Doesnt Elevate Blade, How To Fix?

The person who posted this question about this Craftsman product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Related Craftsman 21833 Manual Pages

Similar Questions

Arbor Nut For A Craftsman Professional Table Saw

(Posted by jimszawara 6 months ago)

Difficulty Raising/lowering Saw Blade

MY model 21829 table saw has become VERY resistant to raising and lowering the blade. I have lubrica...

MY model 21829 table saw has become VERY resistant to raising and lowering the blade. I have lubrica...

(Posted by rpdickenson 8 years ago)

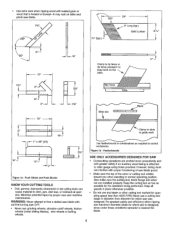

Safe Height For Table Saw Blade Above Material

What is the recommended safe height for the saw blade to protrude above the material being cut? I sa...

What is the recommended safe height for the saw blade to protrude above the material being cut? I sa...

(Posted by leon18666 10 years ago)

Saw Jams

I have a Craftsman 10" Professional Contractor table saw and I can not even cut through 1/2" boards ...

I have a Craftsman 10" Professional Contractor table saw and I can not even cut through 1/2" boards ...

(Posted by bduffy17374 11 years ago)

Dado Throat Plate

Im using a craftsman professional table saw model 315.218280 with a 8 inch dado blade, the dado blad...

Im using a craftsman professional table saw model 315.218280 with a 8 inch dado blade, the dado blad...

(Posted by erosrpella 11 years ago)