Craftsman 21829 Support Question

Find answers below for this question about Craftsman 21829 - Professional 10 in. Portable Table Saw.Need a Craftsman 21829 manual? We have 1 online manual for this item!

Question posted by leon18666 on January 7th, 2014

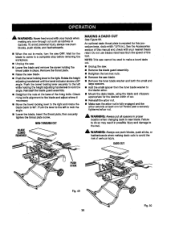

Safe Height For Table Saw Blade Above Material

What is the recommended safe height for the saw blade to protrude above the material being cut? I say the blade should be no more than 1/8" above the material to minimize damage should you make conatct with the blade. 1/8" in most cases would be a minimal flesh wound likely not requiring medical attention. I have carpenters who make various arguements for have more blade protruding such as; It cuts easier with more blade, It makes a cleaner better cut and of course I have been doing this for X number of years it wont happen to me. Help please.

Current Answers

Related Craftsman 21829 Manual Pages

Similar Questions

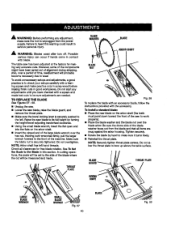

Difficulty Raising/lowering Saw Blade

MY model 21829 table saw has become VERY resistant to raising and lowering the blade. I have lubrica...

MY model 21829 table saw has become VERY resistant to raising and lowering the blade. I have lubrica...

(Posted by rpdickenson 8 years ago)

Changing Table Saw Motor To 240v

I have a 10" Craftsman table saw model #152221140. Lost the cover to the wiring which has the diagra...

I have a 10" Craftsman table saw model #152221140. Lost the cover to the wiring which has the diagra...

(Posted by mridude 9 years ago)

Fence On Craftsman Table Saw 315.218290 Moves To Right When Tightened

(Posted by birahel 10 years ago)

Table Saw Switch Malfunction

Today I pushed my switch on the table saw and it didn't turn off! I had to unplug the table saw. I s...

Today I pushed my switch on the table saw and it didn't turn off! I had to unplug the table saw. I s...

(Posted by gringoticahouse 11 years ago)

What Is A Sears Electronic 10'table Saw Worth

what is a sears electronic 10" table saw w/ext,& base model 113.290650 worth?, it works great

what is a sears electronic 10" table saw w/ext,& base model 113.290650 worth?, it works great

(Posted by mastercook76 11 years ago)