Craftsman 21237 Support Question

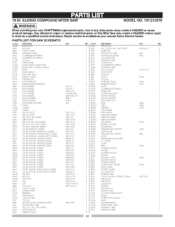

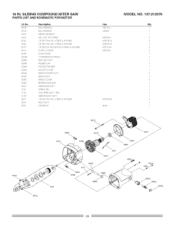

Find answers below for this question about Craftsman 21237 - 10 in. Sliding Miter Saw.Need a Craftsman 21237 manual? We have 1 online manual for this item!

Question posted by mastercook76 on August 27th, 2012

What Is A Sears Electronic 10'table Saw Worth

what is a sears electronic 10" table saw w/ext,& base model 113.290650 worth?, it works great

Current Answers

Related Craftsman 21237 Manual Pages

Similar Questions

Table Saw Model 218290

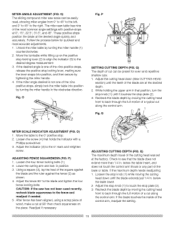

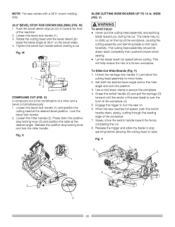

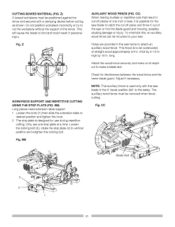

i need instruction to use sliding miter angles

i need instruction to use sliding miter angles

(Posted by shankarbn 9 years ago)

I Have A Craftsman Compound Saw Model 113.234633c.were Can I Get A Replacement?

(Posted by francesandjack 11 years ago)

How Do I Adjust My Craftsman 10' Bandsaw Blade 214 Model

(Posted by Dougdavid 11 years ago)

Is A Table Saw Motor From A Model 21807 Compatible With Other Saws?

will the 3HP 15 amp motor from a model 21807 mount properly on a model 137.248880 table saw (both ar...

will the 3HP 15 amp motor from a model 21807 mount properly on a model 137.248880 table saw (both ar...

(Posted by deannarandy 13 years ago)