Craftsman 21829 Support Question

Find answers below for this question about Craftsman 21829 - Professional 10 in. Portable Table Saw.Need a Craftsman 21829 manual? We have 1 online manual for this item!

Question posted by shankarbn on May 31st, 2014

Table Saw Model 218290

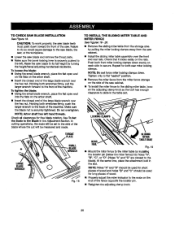

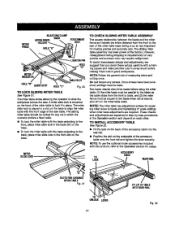

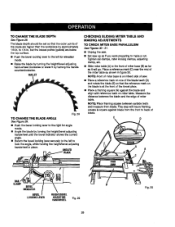

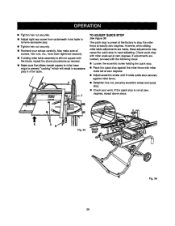

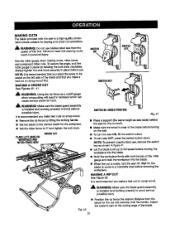

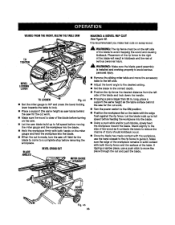

i need instruction to use sliding miter angles

Current Answers

Answer #1: Posted by TechSupport101 on June 1st, 2014 4:10 AM

Hi. The product's Operation Manual is available here http://www.helpowl.com/manuals/Craftsman/21829/30493

Related Craftsman 21829 Manual Pages

Similar Questions

Changing Table Saw Motor To 240v

I have a 10" Craftsman table saw model #152221140. Lost the cover to the wiring which has the diagra...

I have a 10" Craftsman table saw model #152221140. Lost the cover to the wiring which has the diagra...

(Posted by mridude 9 years ago)

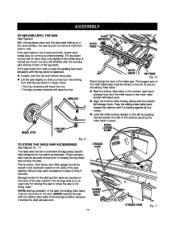

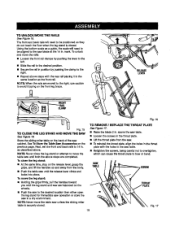

How To Assemble A Portable Craftsman 21829 Table Saw

(Posted by ceclau 9 years ago)

Fence On Craftsman Table Saw 315.218290 Moves To Right When Tightened

(Posted by birahel 10 years ago)

Table Saw Switch Malfunction

Today I pushed my switch on the table saw and it didn't turn off! I had to unplug the table saw. I s...

Today I pushed my switch on the table saw and it didn't turn off! I had to unplug the table saw. I s...

(Posted by gringoticahouse 11 years ago)

Is A Table Saw Motor From A Model 21807 Compatible With Other Saws?

will the 3HP 15 amp motor from a model 21807 mount properly on a model 137.248880 table saw (both ar...

will the 3HP 15 amp motor from a model 21807 mount properly on a model 137.248880 table saw (both ar...

(Posted by deannarandy 13 years ago)