Craftsman 21609 Support Question

Find answers below for this question about Craftsman 21609 - 18 in. Scroll Saw.Need a Craftsman 21609 manual? We have 1 online manual for this item!

Question posted by jimwjohnson1949 on January 5th, 2013

Power And Control Cards.

I need the power and control cards for my saw, saw has not been used much. but cards need to be replaced, one of them is bad and i want to replace both cards, is there any place that I can get them, thank you jim

Current Answers

Related Craftsman 21609 Manual Pages

Similar Questions

Motor Carbon Brushes

Hello....I'm looking for substitute parts, the original are not longer available.It's for a Craftsma...

Hello....I'm looking for substitute parts, the original are not longer available.It's for a Craftsma...

(Posted by jriofrio 10 months ago)

16' Scroll Saw Variable Switch Assembly

I need a 16" Scroll Saw Variable Switch Assembly

I need a 16" Scroll Saw Variable Switch Assembly

(Posted by ldsilva1 9 years ago)

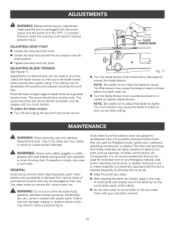

Craftsman 18 Inch Variable Speed Scroll Saw Model 315.216090

I would like pictures or diagrams of pc board/s connections. Any problems with yours?

I would like pictures or diagrams of pc board/s connections. Any problems with yours?

(Posted by dianechristensen5054 9 years ago)

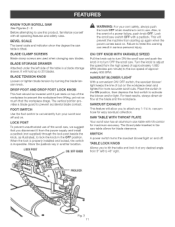

Can't Tighten Blades There Is No Tension

Blade tensioner doesn't have any tension. I tey tightening the balde and it won't tighten. Please he...

Blade tensioner doesn't have any tension. I tey tightening the balde and it won't tighten. Please he...

(Posted by jcvw57 10 years ago)

Maximum Cut Depth For 21609 Scroll Saw

I can't find the maximum depth of cut that you can make with the 21609 scroll saw - can you please t...

I can't find the maximum depth of cut that you can make with the 21609 scroll saw - can you please t...

(Posted by brian78088 12 years ago)