Craftsman 21609 Support Question

Find answers below for this question about Craftsman 21609 - 18 in. Scroll Saw.Need a Craftsman 21609 manual? We have 1 online manual for this item!

Question posted by brian78088 on June 8th, 2011

Maximum Cut Depth For 21609 Scroll Saw

I can't find the maximum depth of cut that you can make with the 21609 scroll saw - can you please tell me what it is?

Current Answers

Related Craftsman 21609 Manual Pages

Similar Questions

Motor Carbon Brushes

Hello....I'm looking for substitute parts, the original are not longer available.It's for a Craftsma...

Hello....I'm looking for substitute parts, the original are not longer available.It's for a Craftsma...

(Posted by jriofrio 10 months ago)

16' Scroll Saw Variable Switch Assembly

I need a 16" Scroll Saw Variable Switch Assembly

I need a 16" Scroll Saw Variable Switch Assembly

(Posted by ldsilva1 9 years ago)

Craftsman 18 Inch Variable Speed Scroll Saw Model 315.216090

I would like pictures or diagrams of pc board/s connections. Any problems with yours?

I would like pictures or diagrams of pc board/s connections. Any problems with yours?

(Posted by dianechristensen5054 9 years ago)

It Is Getting Power. The Light Works But The Saw Will Not Operate.

(Posted by Anonymous-123838 10 years ago)

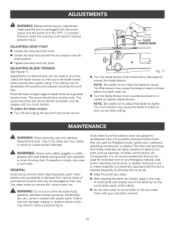

Can't Tighten Blades There Is No Tension

Blade tensioner doesn't have any tension. I tey tightening the balde and it won't tighten. Please he...

Blade tensioner doesn't have any tension. I tey tightening the balde and it won't tighten. Please he...

(Posted by jcvw57 10 years ago)