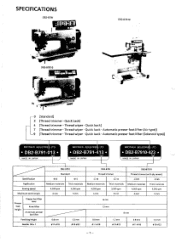

Brother International DB2-B791 Support Question

Find answers below for this question about Brother International DB2-B791.Need a Brother International DB2-B791 manual? We have 1 online manual for this item!

Question posted by STARLINER on April 17th, 2015

Is There A Separate Manual For The Db2-b791-405?

The person who posted this question about this Brother International product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Related Brother International DB2-B791 Manual Pages

Similar Questions

Manual In Portuguese Brother Sewing Machine Pc6500

How can I get this manual in portuguese of Brazil?

How can I get this manual in portuguese of Brazil?

(Posted by rosana33 9 years ago)

Where Is A Parts Guide Or Service Manual For Brother Jx2517 Sewing Machine?

the inside of my brother JX2517 sewing machine broke. Its a plastic piece,gear, at end by the needle...

the inside of my brother JX2517 sewing machine broke. Its a plastic piece,gear, at end by the needle...

(Posted by Discogypsy 9 years ago)

Where Can I Find An Instructional Manual Or Brother Xr1300 Sewing Machine To Buy

(Posted by calverts50 10 years ago)

I Want To Print Out The Manual For Brother Xl2600i Sewing Machine.i Can't Downlo

(Posted by karhpa 11 years ago)