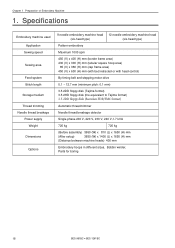

Brother International BES-961BC Support Question

Find answers below for this question about Brother International BES-961BC.Need a Brother International BES-961BC manual? We have 13 online manuals for this item!

Question posted by henryarevalo on November 6th, 2015

I Was Told That I Need To Get A New My Mother Board To My Single Head .do You Kn

I was told that I need a mother board . for my single head.Do you know where I can get one.

Current Answers

Answer #1: Posted by TechSupport101 on November 6th, 2015 8:55 PM

Hi. I am not finding a third party parts retailer with the parts for the model in question. I therefore suggest you you lookup your nearest authorized Brother Service Center with the help of the facility here http://www.brother-usa.com/service/ and then contact then for a more hopeful way to source the main board.

Related Brother International BES-961BC Manual Pages

Similar Questions

What Kind Of Needle Do I Need For My Sewing Machine Brother Ls 1520

(Posted by cmb93sor 9 years ago)

I Have A New Brother Pe 780d Sewing Machine. It Keeps Tangling In The Bobin Ca

the tangle is the upper thread?

the tangle is the upper thread?

(Posted by jareds5 10 years ago)

What Size Of Needle Do I Need To Use In Brother Sewing Machine Vx 1120

(Posted by amjackpage 10 years ago)

I Need A Repair Manual For The Se270d Embroidery/sewing Machine. Error F05

I need a repair manual for the Brother SE270D Embroidery/Sewing Machine, to fix error F05. The cost ...

I need a repair manual for the Brother SE270D Embroidery/Sewing Machine, to fix error F05. The cost ...

(Posted by romaplovell 10 years ago)

I Need A Parts And Schematic Manual For Sewing Machine Xl-3200 Brother

(Posted by MANUALS1 10 years ago)