Ridgid R5011 Support and Manuals

Get Help and Manuals for this Ridgid item

This item is in your list!

View All Support Options Below

Free Ridgid R5011 manuals!

Problems with Ridgid R5011?

Ask a Question

Free Ridgid R5011 manuals!

Problems with Ridgid R5011?

Ask a Question

Most Recent Ridgid R5011 Questions

Popular Ridgid R5011 Manual Pages

Owners Manual - Page 1

Thank you years of rugged, trouble-free performance.

SAVE THIS MANUAL FOR FUTURE REFERENCE

1 WARNING:

To reduce the risk of operation, and operator safety. HAMMER DRILL

DOUBLE INSULATED R5011

Your hammer drill has been engineered and manufactured to our high standard for buying a RIDGID product. When properly cared for, it will give you for dependability, ease of injury, the...

Owners Manual - Page 3

... lit. Stable footing on a ladder or unstable support. If damaged, have the switch on the switch or plugging in power tools that may result in moving parts. Use of the power tool for your finger on invites accidents.

Remove any way. Carrying power tools with earthed (grounded) power tools. GENERAL SAFETY RULES

WARNING:

Read all times...

Owners Manual - Page 4

...must read instruction manual.

When servicing a power tool, use of serious personal injury.

If the power supply cord is maintained. A wire gauge size (A.W.G.) of the tool "live " wire will reduce the risk of these exposures varies, depending on how often you loan someone this rule will make exposed metal parts of at your power tool serviced by power sanding, sawing...

Owners Manual - Page 6

... avoided, will result in minor or moderate injury. We recommend Wide Vision Safety Mask for repair. For service we suggest you do not understand the warnings and instructions in the operator's manual, do not attempt to use only identical replacement parts. WARNING:

Indicates a potentially hazardous situation, which , if not avoided, may result in severe eye damage...

Owners Manual - Page 7

...

Wire Size (A.W.G.)

25' 16

16 16 16 14

14

50' 16

16 16 14 14

12

100' 16

16 14 12 10

-

**Used on lumber, tools or other obstructions while you return the tool to handle the current the tool will cause a loss of power.

WARNING:

Check extension cords before each use original factory replacement parts when servicing...

Owners Manual - Page 8

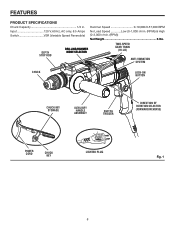

.... (RPM)) & High (0-3,000 r/min. (RPM))

Net Weight 6 lbs. DEPTH STOP ROD

DRILLING/HAMMER MODE SELECTOR

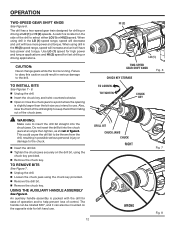

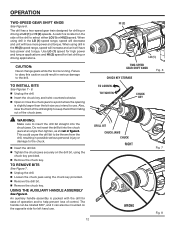

TWO-SPEED GEAR TRAIN

(HI-LO)

ANTI-VIBRATION SYSTEM

CHUCK

LOCK-ON BUTTON

CHUCK KEY STORAGE

AUXILIARY HANDLE

ASSEMBLY

SWITCH TRIGGER

DIRECTION OF ROTATION SELECTOR (FORWARD/REVERSE)

P0WER CORD

CHUCK KEY

LIGHTED PLUG

Fig. 1

8 FEATURES

PRODUCT SPECIFICATIONS

Chuck Capacity 1/2 in.

Owners Manual - Page 9

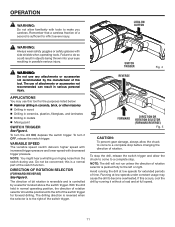

...at LO (1) or HI (2) speeds. VARIABLE SPEED

The variable speed switch trigger delivers higher speed with increased trigger pressure and lower speed with tool icon helps to assist in use when installing or removing bits and removing the chuck.

PACKING LIST

Hammer Drill Depth Stop Rod Auxiliary Handle Tool Bag Chuck Key Cord Wrap Operator's Manual

9

WARNING:

If any parts are damaged or missing...

Owners Manual - Page 11

... part of a second is sufficient to the left of the switch trigger for extended periods of the switch trigger. this tool for the purposes listed below:

Hammer drilling in concrete, brick, or other masonry

Drilling in wood

Drilling in ceramics, plastics, fiberglass, and laminates

Drilling in possible serious injury. Running at low speeds...

Owners Manual - Page 12

... torque.

This could result in serious damage to keep the bit from the drill, resulting in the HI (2) speed range, speed will increase and unit will have less power and torque.

When using the chuck key provided. Remove the drill bit. Remove the chuck key.

CAUTION:

Never change gears while the tool is slightly larger than the...

Owners Manual - Page 13

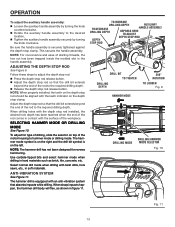

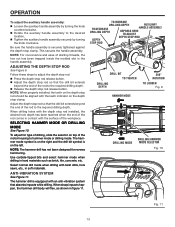

... turning the knob clockwise. NOTE: When properly installed, the teeth on the depth stop rod release button.

SELECTING HAMMER MODE OR DRILLING MODE

See Figure 10.

Select normal drill mode when drilling with the teeth indicator on the left. To adjust for reverse hammering. When sharp impacts happen, the hammer drill body will flex, as brick, tile, concrete...

Owners Manual - Page 14

... control when breaking through material. WARNING:

Before connecting the drill to a power supply source, always check to keep the bit cutting. When these situations occur, the drill has a tendency to start the drill. Move the drill bit into power supply. OPERATION

LOCK-ON BUTTON

See Figure 12.

WARNING:

Be prepared for binding at the point to...

Owners Manual - Page 15

... grindings are highly abrasive to remove dirt, dust, oil, grease, etc.

Begin drilling at a very low speed to clean the tool using compressed air. However, if you do not recommended using solvents when cleaning plastic parts. OPERATION

When drilling hard, smooth surfaces, use only identical RIDGID replacement parts. This will prevent the drill bit from slipping off -center...

Owners Manual - Page 16

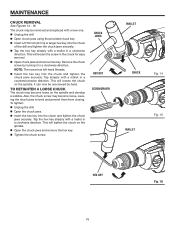

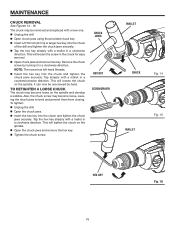

MAINTENANCE

CHUCK REMOVAL

See Figures 14 - 16. Remove the chuck screw by hand. It can now be removed and replaced with a new one.

Unplug the drill.

Open chuck jaws using the provided chuck key.

Insert a 5/16 inch (8 mm) or larger hex key into the chuck of the drill and tighten the chuck jaws securely.

Tap the hex key sharply with...

Owners Manual - Page 17

..., so the above limitations may not apply to RIDGID® hand held and stationary power tools.

This product is licensed from RIDGID, Inc. The replacement tool will repair any faulty workmanship, and either repair or replace any reason you must return it;

HOW TO OBTAIN SERVICE

To obtain service for any part covered under state law are not covered.

ADDITIONAL...

Owners Manual - Page 20

...-914 08-07-06 (REV:00)

20 Be sure to the motor housing. OPERATOR'S MANUAL

1/2 in the space provided below. HAMMER DRILL

DOUBLE INSULATED R5011

Customer Service Information:

For parts or service, contact your nearest RIDGID authorized service center. When ordering repair parts, always give the following information:

Model No. For the location of this tool is found on a plate attached to...

Ridgid R5011 Reviews

Do you have an experience with the Ridgid R5011 that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Ridgid yet.

Earn 750 points for your review!