Kenmore 16677 - Serger Sewing Machine Support and Manuals

Get Help and Manuals for this Kenmore item

View All Support Options Below

Free Kenmore 16677 manuals!

Problems with Kenmore 16677?

Ask a Question

Free Kenmore 16677 manuals!

Problems with Kenmore 16677?

Ask a Question

Most Recent Kenmore 16677 Questions

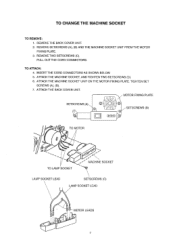

How Do I Replace The Light Bulb

(Posted by jandchatcher 11 years ago)

Please Tell Me How To Download The Manual From This Site

need to download or copy the manual , but dont find the way to do it . cuase it only has the copy bu...

need to download or copy the manual , but dont find the way to do it . cuase it only has the copy bu...

(Posted by irismable 11 years ago)

Oil And Maintenance

Hi I would like to use this serger but it has been standing for some time and there is no user manu...

Hi I would like to use this serger but it has been standing for some time and there is no user manu...

(Posted by dubrita 12 years ago)

Cover Hem Stitch

I am new to sewing and serging. I am trying to figure out how to do a cover hem stitch.

I am new to sewing and serging. I am trying to figure out how to do a cover hem stitch.

(Posted by dutdesx3 13 years ago)

Kenmore 16677 Videos

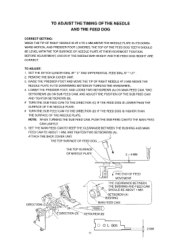

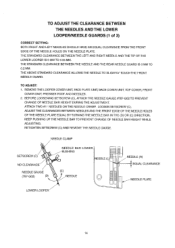

Popular Kenmore 16677 Manual Pages

Kenmore 16677 Reviews

We have not received any reviews for Kenmore yet.