Ryobi TSS101L Support Question

Find answers below for this question about Ryobi TSS101L.Need a Ryobi TSS101L manual? We have 4 online manuals for this item!

Question posted by pgrossman on December 15th, 2011

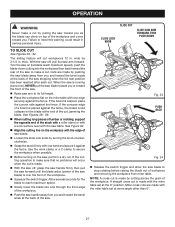

Exhaust Of Sawdust

I have used my miter saw today and it works great. BUT The exhaust bag is not filling with saw dust ... the saw dust just shoots out the bottom of the blade and all over. I attached the bag correctly.

Please help.

Current Answers

Related Ryobi TSS101L Manual Pages

Similar Questions

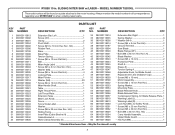

Is There A Replacement For Ryobi Tss101l D Handle & Switch?

Part #s for above: 089100121610 089100121112 Have apparently discontinued. Does anyone have a fix?

Part #s for above: 089100121610 089100121112 Have apparently discontinued. Does anyone have a fix?

(Posted by Math72285 3 years ago)

I Have To Remove Arm Support Bracket To Replace It After A Falling Accident

dear sirs I removed two little nuts and am stocked with lock pins , so what tool do you use to remov...

dear sirs I removed two little nuts and am stocked with lock pins , so what tool do you use to remov...

(Posted by thguenand 8 years ago)

How Do I Replace The Lower Guard Of A 10' Compound Miter Saw(ts1342l)

(Posted by mvegab 8 years ago)

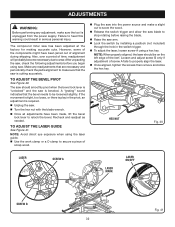

Needs Adjustment

I have a Ryobi 10in TSS101L compound miter saw. As I make a cut while it is zero'd out it continues ...

I have a Ryobi 10in TSS101L compound miter saw. As I make a cut while it is zero'd out it continues ...

(Posted by keitheburns 11 years ago)

Why Is It After One Use My Saw Wont Even Fire

this is the 2nd zrry 10520 i had to get after one use the stop firing

this is the 2nd zrry 10520 i had to get after one use the stop firing

(Posted by Anonymous-53200 12 years ago)