Ryobi RTS10 Support Question

Find answers below for this question about Ryobi RTS10.Need a Ryobi RTS10 manual? We have 4 online manuals for this item!

Question posted by ivabkbow on June 24th, 2014

Rts10 Wont Turn On

The person who posted this question about this Ryobi product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Related Ryobi RTS10 Manual Pages

Similar Questions

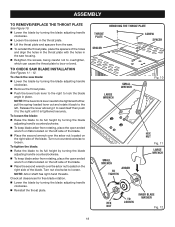

Ryobi Rts10 Riving Lever Won't Lock

The riving knife lever on Ryobi RTS10 won't lock. Is there anything that shows the assembly of this ...

The riving knife lever on Ryobi RTS10 won't lock. Is there anything that shows the assembly of this ...

(Posted by nsmerk 8 years ago)

Dado Blade Insert For A Ryobi Rts10 Table Saw

Where can I purchase a dado blade insert for my Ryobi RTS10 10" table saw? I am having difficulty fi...

Where can I purchase a dado blade insert for my Ryobi RTS10 10" table saw? I am having difficulty fi...

(Posted by bstilton 9 years ago)

Rts10 Dado Throat Cover

I need a dado throat cover for a Ryobi RTS10 table saw

I need a dado throat cover for a Ryobi RTS10 table saw

(Posted by mattharbaugh 10 years ago)

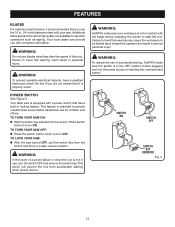

Rts10/bts16

Is the motor on the RTS10, the same motor as is on the BTS16?

Is the motor on the RTS10, the same motor as is on the BTS16?

(Posted by kesev 11 years ago)