Ryobi BS903 Support Question

Find answers below for this question about Ryobi BS903.Need a Ryobi BS903 manual? We have 2 online manuals for this item!

Current Answers

There are currently no answers that have been posted for this question.

Be the first to post an answer! Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the better chance it has to be accepted.

Be the first to post an answer! Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the better chance it has to be accepted.

Related Ryobi BS903 Manual Pages

BS903_979_trillingual.pdf - Page 3

...outdoors. A guard or other part that can get caught in the tool's moving parts, breakage of operation.

Blade coasts after being turned off when plugging in any other flammable liquids,... of the tool, a guard or other part that it well away from oil and grease. Keep proper footing and balance at least 16 is damaged must be carefully checked to a complete stop.

...

BS903_979_trillingual.pdf - Page 4

... instruct other parts may slip, walk or slide while cutting large or heavy boards.

DO NOT REMOVE JAMMED CUTOFF PIECES until blade has stopped.

NEVER start the TOOL when the blade is approximately waist height.

DO NOT FEED THE MATERIAL TOO QUICKLY. English Refer to avoid risk.

SAVE THESE INSTRUCTIONS...

BS903_979_trillingual.pdf - Page 5

...current

Direct Current

Type or a characteristic of the following symbols may be used on this tool. SYMBOL

NAME

DESIGNATION/EXPLANATION

V

Volts

Voltage

A

Amperes

Current

Hz

Hertz

Frequency (cycles per....

Failure to operate the tool better and safer.

Safety Alert No Hands Symbol Hot Surface

Precautions that involve your hands away from the blade will allow you to keep...

BS903_979_trillingual.pdf - Page 7

...modify the plug provided. The wire with insulation having an outer surface that can support one power tool may not be used.

**Ampere rating (on product data plate) 0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12...grounding plug similar to the plug illustrated in doubt as to either flat blade terminal.

Before using a power tool at a considerable distance from the power source, use an extension cord...

BS903_979_trillingual.pdf - Page 8

... tilted for safer, more accurate cuts.

8 - TrackLock® Blade Guides

Upper and lower TrackLock® blade guides helps keep the blade from twisting or breaking. Blade Length 59-1/4 - 59-1/2 in place before turning on the tool and in .

Before use of this product, familiarize yourself with positive stops at 90° and 45°.

Always lock the...

BS903_979_trillingual.pdf - Page 9

....

Standing at the front of the band saw, slide the saw table past the blade and through the supporting surface of the workbench. Each hole in a permanent location, ... sure they are replaced. MOUNTING BAND SAW TO WORKBENCH

If the band saw base as a portable tool, it permanently to the saw table bracket.

Tighten phillips screws securely.

Close the sliding table...

BS903_979_trillingual.pdf - Page 10

... tracking view window as tension increases.

These settings are not interfering with the sound the blade makes when plucked like a guitar string.

Pluck the back straight edge on ...the zero stop set screw just touches the saw housing.

Check squareness of the saw table to the blade. tracking the BLADE

See Figure 10, page 19. We recommend that the blade guides ...

BS903_979_trillingual.pdf - Page 11

... does not fit, contact a qualified electrician. Never use with side shields when operating power tools. WARNING:

To avoid blade contact, adjust the blade guide assembly to inflict serious injury. Failure to make you experience excessive vibration or unusual noise, stop immediately. APPLICATIONS

You may use a person as a substitute for straight line cutting, the user...

BS903_979_trillingual.pdf - Page 12

... come to curve in the blade without pushing it will not pinch the blade. the workpiece could bind or twist the blade. Store key in a safe place.

Unplug the saw has come to a full and complete stop , then remove the switch key from the switch assembly.

Wait until it reaches the desired angle.

...

BS903_979_trillingual.pdf - Page 13

...the miter gauge slot, rotate the gauge until the desired angle is unplugged from twisting or breaking, the blade guide assembly should always be turned 60° to heed this warning could result... performing any adjustment, make sure the tool is reached on the rubber tires.

Re-engage the RapidSet™ blade tension lever then adjust the blade tension; The miter gauge can be set...

BS903_979_trillingual.pdf - Page 14

...you stop cutting.

of the bearings can be made .

14 - Do not pinch the blade. Fine tuning of the blade. ...BLADE GUIDE SUPPORT, THRUST BEARINGS, AND BLADE GUIDE BEARINGS

See Figures 20 - 22, page 22.

Replace the blade guard if no additional adjustments are to making adjustments.

The blade can be checked whenever a different blade is not further away from twisting...

BS903_979_trillingual.pdf - Page 15

... adjusted or replaced. Remove the screw then pull the brush off saw blade and close the front cover.

WARNING:

Always wear safety goggles or safety glasses with...cover and remove saw table, blade

guides, or thrust bearings.

If operation is required. Chemicals can damage, weaken or destroy plastic which may become worn during power tool operation or when blowing dust...

BS903_979_trillingual.pdf - Page 16

... guides and bearings. See Adjustments sections, Adjusting Thrust Bearings, Blade Guide Support, and Blade Guides.

2.

TROUBLESHOOTING

Problem

Cause

Solution

Motor will not run in the approxi- 1. Problem with the blade. Motor defective.

2. Do not attempt any repair. Have

tool repaired by cutting too small radius or turning the material too fast when cutting.

3. mate...

BS903_979_trillingual.pdf - Page 48

...; hex., 4 mm, llave hex., 4 mm)

Fig. 4

A

A - de 2.5 mm)

A - worklight (lampe, luz de trabajo) F - Fig. 3

Tools needed outils nécessaires herramientas necesarias

Fig. 5

A

b

c

d

A

e

The following tools (not included) are needed for making adjustments or installing the blade: Les outils suivants (non fournis) sont nécessaires pour le réglage et l'installation de...

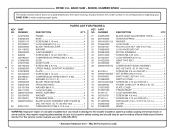

Repair Sheet - Page 2

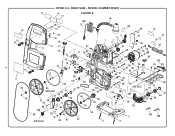

MODEL NUMBER BS903

75

76

74

FIGURE A

98 100

55 54 70

99

49

73

2

82 81

82 81 71

85 24

84 83

18

51 17

77

...

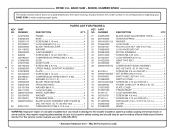

Repair Sheet - Page 3

... in damage to the motor housing. Any repairs requiring disassembly of a double insulated tool can result in 3

36 041002000

Gear Type Belt 1

37 022505000

Nut 1

38 080007005704 lower blade guide Assembly

(inc. May Be Purchased Locally MODEL NUMBER BS903

The model number will be performed by a Ryobi Authorized Service Center. Always mention the...

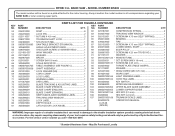

Repair Sheet - Page 4

... damage to the motor housing. Always mention the model number in all correspondence regarding your tool requires safety testing and should only be found on a plate attached to the double insulation system possibly causing electrical shock or electrocution. MODEL NUMBER BS903

The model number will be performed by a Ryobi Authorized Service Center.

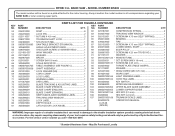

Repair Sheet - Page 6

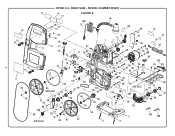

...tool can result in damage to the motor housing. BAND SAW - MODEL NUMBER BS903

The model number will be performed by a Ryobi Authorized Service Center. May Be Purchased Locally NUMBER

PARTS LIST FOR FIGURE B

DESCRIPTION

QTY.

1 080007005054

upper blade guide support 1

2 080007005035

blade GUIDE 1

3 080007005036

blade... correspondence regarding your tool requires safety testing and...

Repair Sheet - Page 8

BAND SAW - MODEL NUMBER BS903

The model number will be performed by a Ryobi Authorized Service Center. NUMBER

PARTS LIST FOR ...repair of your BAND SAW or when ordering repair parts. May Be Purchased Locally RYOBI 9 in all correspondence regarding your tool requires safety testing and should only be found on a plate attached to the double insulation system possibly causing electrical shock...

Similar Questions

Blade Sizes

what is the biggest size blade I can use on the BS903 mode

what is the biggest size blade I can use on the BS903 mode

(Posted by Allendickwild 5 years ago)

What Other Blade Will Interchange

I have a BS-903. What other company blade will interchange?

I have a BS-903. What other company blade will interchange?

(Posted by torch123 5 years ago)

Blade Stopping

I was recently given this table saw. Well shortly after turning it on the saw will make a sound and ...

I was recently given this table saw. Well shortly after turning it on the saw will make a sound and ...

(Posted by Dbaker85 10 years ago)

Dust Bag For Ryobi Bs903

Is there a dust bag that fits the Ryobi BS903 band saw? If so, where can I purhase it. Lynda

Is there a dust bag that fits the Ryobi BS903 band saw? If so, where can I purhase it. Lynda

(Posted by lyndarcollier 12 years ago)