Ridgid R4512 Support Question

Find answers below for this question about Ridgid R4512.Need a Ridgid R4512 manual? We have 1 online manual for this item!

Question posted by carhodenizer on March 1st, 2022

Replacement Parts

Current Answers

Answer #1: Posted by SonuKumar on March 2nd, 2022 7:21 AM

https://www.toolpartspro.com/ridgid-parts/ridgid-r4512-parts.html

https://www.ereplacementparts.com/ridgid-r4512-inch-table-saw-parts-c-7929_8171_162373.html

https://www.repairtoolparts.com/ridgid-parts/ridgid-r4512-parts-list

https://www.partswarehouse.com/Ridgid-R4512-10-Table-Saw-s/159237.htm

https://picclick.com/Ridgid-R4512-Saw-Table-Parts-Main-Table-322226187951.html

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Ridgid R4512 Manual Pages

Similar Questions

please supply part number for new motor. Mine is smoked. Thank you

Upper plastic bumper disintegrated, Part HM079005004079 is discontinued and no other replacement par...

Hi, I am looking for the fence for the MS255SR. It has been difficult to find the part number. If I ...

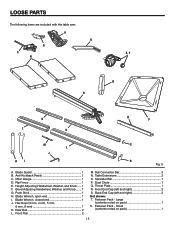

Can anyone help me find these parts or some suitable replacement parts?