Ridgid GP80145SW Support Question

Find answers below for this question about Ridgid GP80145SW.Need a Ridgid GP80145SW manual? We have 2 online manuals for this item!

Question posted by tmalkus on September 15th, 2014

How To Repair Pressure Regulator Valve

The person who posted this question about this Ridgid product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

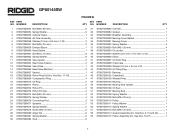

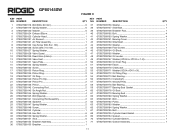

Related Ridgid GP80145SW Manual Pages

Similar Questions

Shop Repair Manual

Am looking for a shop/repair manual (not the owner manual) for a Ridgid R4331 bench top planer.

Am looking for a shop/repair manual (not the owner manual) for a Ridgid R4331 bench top planer.

(Posted by jimshoe52 8 years ago)

How Do You Remove The Spring Pins In Order To Remove The Trigger Valve Assembly

Rigid Framing Nailer RH350RHE:I have a rebuild kit that includes a new trigger valve assembly (part ...

Rigid Framing Nailer RH350RHE:I have a rebuild kit that includes a new trigger valve assembly (part ...

(Posted by ardvark02 9 years ago)

Tristack Compressor Repair

fills up to only 50 psi. it will keep running but not gain anymore pressure.cant detect any leaks in...

fills up to only 50 psi. it will keep running but not gain anymore pressure.cant detect any leaks in...

(Posted by bryanh222 10 years ago)

Ridged Gp80145sw Compressor

Cannot find the muffler for this compressor.

Cannot find the muffler for this compressor.

(Posted by benc07717 10 years ago)