Ridgid R350RHE Support Question

Find answers below for this question about Ridgid R350RHE.Need a Ridgid R350RHE manual? We have 2 online manuals for this item!

Question posted by ardvark02 on April 8th, 2015

How Do You Remove The Spring Pins In Order To Remove The Trigger Valve Assembly

Rigid Framing Nailer RH350RHE:I have a rebuild kit that includes a new trigger valve assembly (part #25). In order to replace it the two spring pins (part #81) have to be removed. How are these pins removed?

Current Answers

Answer #1: Posted by TommyKervz on April 11th, 2015 1:33 AM

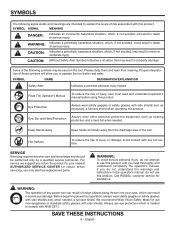

If any parts are damaged or missing, please call 1-866-539-1710 for assistance. go here for some basic troubleshooting.

Answer #2: Posted by TommyKervz on April 9th, 2015 4:08 AM

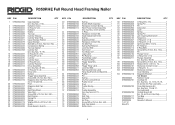

Please refer to the repair sheet' download below

Related Ridgid R350RHE Manual Pages

Similar Questions

Assembly Motor

Do Rigid grinders have a lifetime warranty. They no longer make my grinder R1005 and needs a new ass...

Do Rigid grinders have a lifetime warranty. They no longer make my grinder R1005 and needs a new ass...

(Posted by jeffhudec13 1 year ago)

R5013 Wiring Diagram For Trigger Switch

Is there a wiring diagram somewhere that shows proper wire connections for the trigger switch.Thank ...

Is there a wiring diagram somewhere that shows proper wire connections for the trigger switch.Thank ...

(Posted by Robpotter 3 years ago)

Assembly Riving Knife Part # 089037004708

I am looking for the Assembly Riving Knife Part # 089037004708 for the10 in. Table Saw R4510, I have...

I am looking for the Assembly Riving Knife Part # 089037004708 for the10 in. Table Saw R4510, I have...

(Posted by dgeorge42854 6 years ago)

On/off Switch Cover Removal

It looks like my electrical wires are loose coming into the on/off switch. How do I remove the switc...

It looks like my electrical wires are loose coming into the on/off switch. How do I remove the switc...

(Posted by grfern50 7 years ago)