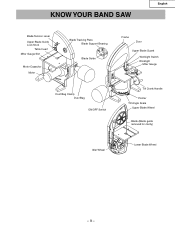

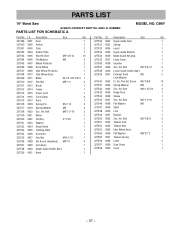

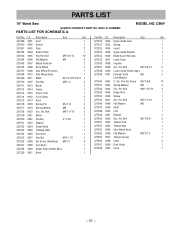

Hitachi CB6YI Support Question

Find answers below for this question about Hitachi CB6YI - 10 Inch Tilting Head Bandsaw.Need a Hitachi CB6YI manual? We have 2 online manuals for this item!

Question posted by davidkeniston on January 2nd, 2012

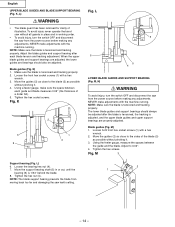

Bandsaw Replacement Guides

my band saw guides have worn out can i buy new guides without having to replace the whole assembly.

Current Answers

Related Hitachi CB6YI Manual Pages

Similar Questions

Replacement Part

My Hitachi NR 90GC bail gun fell and the housing case us broken. Where could I buy a replacement

My Hitachi NR 90GC bail gun fell and the housing case us broken. Where could I buy a replacement

(Posted by Trevoreccleston 1 year ago)

That's The Original Hitachi Japonês?

I'm looking for hitachi miter saw 10" japonês original not the metabo you guys have

I'm looking for hitachi miter saw 10" japonês original not the metabo you guys have

(Posted by Pereirafulr 2 years ago)

Hitachi C10ra3 Compatible Blades.

Can I use an 8 inch blade with this saw? If so, can it be for cutting ceramic tile?

Can I use an 8 inch blade with this saw? If so, can it be for cutting ceramic tile?

(Posted by gwoltman 3 years ago)

How To Square The Head On An Hitachi Miter Saw

(Posted by afajab 9 years ago)

Can I Replace My Old Ni Cad Batteries With Some Lithium Ones.

(Posted by jamessmartcarpentry 11 years ago)