Harbor Freight Tools 61969 Support Question

Find answers below for this question about Harbor Freight Tools 61969 - 12 in. Double-Bevel Sliding Compound Miter Saw.Need a Harbor Freight Tools 61969 manual? We have 1 online manual for this item!

Question posted by Chetmaniak on May 30th, 2023

How Do I Change The Turn Table Plates

Current Answers

Answer #1: Posted by SonuKumar on May 30th, 2023 7:40 PM

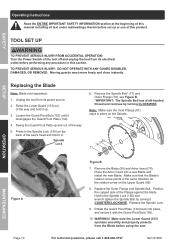

Ensure safety: Make sure the turntable is turned off and unplugged from the power source. This will help prevent any accidental injuries during the plate replacement process.

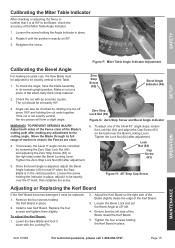

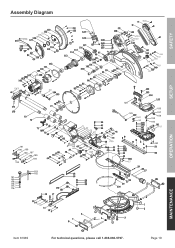

Locate the retaining clips: The turntable plates are typically held in place by retaining clips or similar mechanisms. Locate these clips or mechanisms on the underside of the turntable.

Release the retaining clips: Depending on the specific design of the turntable, you may need to press or lift the retaining clips to release them. This will allow you to remove the existing turntable plates.

Remove the old plates: Once the retaining clips are released, carefully lift and remove the old turntable plates from the turntable. Be cautious not to damage any other components or wiring while doing this.

Clean the turntable: Before installing the new plates, take a moment to clean the turntable surface. Wipe away any debris or residue to ensure a clean and smooth surface for the new plates.

Install the new plates: Take the new turntable plates and align them with the appropriate slots or mounting points on the turntable. Gently press them down to secure them in place.

Engage the retaining clips: Once the new plates are installed, engage the retaining clips or mechanisms to secure them. This may involve pressing or sliding the clips back into position to hold the plates securely.

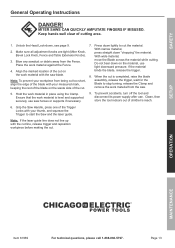

Test the turntable: After replacing the turntable plates, plug the unit back in and turn it on to ensure that it operates properly. Verify that the new plates are rotating smoothly and evenly.

If you encounter any difficulties during the plate replacement process or have concerns about the specific instructions for the Harbor Freight Tools 61969 turntable, it is recommended to consult the user manual provided with the product or reach out to Harbor Freight Tools customer support for further assistance.

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Harbor Freight Tools 61969 Manual Pages

Similar Questions

61969 - Chicago Electric 12 in. Double-Bevel Sliding Compound Miter Saw.I bought this miter saw but ...

looking for outer flange for Chicago electric 19" sliding compound miter saw item 61972

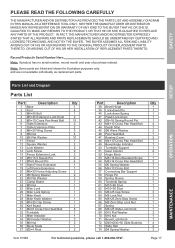

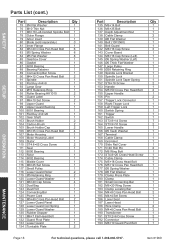

Where can I get part 134 turntable plate?