Harbor Freight Tools 61969 Support Question

Find answers below for this question about Harbor Freight Tools 61969 - 12 in. Double-Bevel Sliding Compound Miter Saw.Need a Harbor Freight Tools 61969 manual? We have 1 online manual for this item!

Question posted by Anonymous-165901 on January 4th, 2020

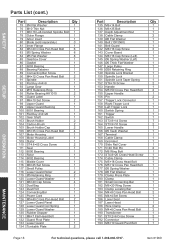

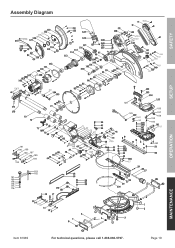

Where Can I Get Part 134 Turntable Plate?

Current Answers

Answer #1: Posted by freginold on January 5th, 2020 6:19 AM

"Note: Some parts are listed and shown for illustration purposes only, and are not available individually as replacement parts."

Answer #2: Posted by Odin on January 4th, 2020 12:01 PM

- Try http://www.searspartsdirect.com/ [call if necessary] or https://encompass.com/.

- Try another online parts source like http://www.ereplacementparts.com/ or https://www.partstore.com/

- Contact local parts dealers and used appliance dealers, who might be able to supply or maybe fix the part

- Use a search engine like Google's or Bing

- Try http://www.searchtempest.com/, which displays global listings from eBay, Craigslist, and other sources

- Take the part you have to an appliance technician, who might possibly be able to fix or replace the part

(For option 5, you may want to use a free tracking program like https://www.followthatpage.com/ to save you from having to repeat your search over time.)

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

Related Harbor Freight Tools 61969 Manual Pages

Similar Questions

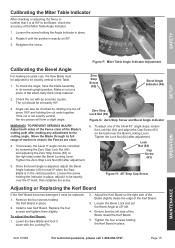

how do I change turntable plate

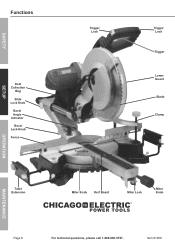

61969 - Chicago Electric 12 in. Double-Bevel Sliding Compound Miter Saw.I bought this miter saw but ...

looking for outer flange for Chicago electric 19" sliding compound miter saw item 61972