Craftsman 22124 Support Question

Find answers below for this question about Craftsman 22124 - Professional 10 in. Table Saw.Need a Craftsman 22124 manual? We have 1 online manual for this item!

Question posted by Spauldid51 on April 29th, 2013

Or91721 Replacement Belt

What is a replacement belt that can purchased with out a month relay from order from Sears Parts?

Current Answers

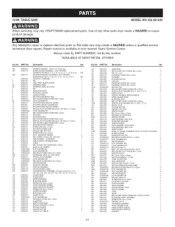

Related Craftsman 22124 Manual Pages

Similar Questions

Arbor Nut For A Craftsman Professional Table Saw

(Posted by jimszawara 7 months ago)

Is There Any Place You Know Of Where I Can Get The Table Saw Arbor Nut #or91050?

Any hints would be appreciated

Any hints would be appreciated

(Posted by Chuckmorley 1 year ago)

Table Saw Switch Malfunction

Today I pushed my switch on the table saw and it didn't turn off! I had to unplug the table saw. I s...

Today I pushed my switch on the table saw and it didn't turn off! I had to unplug the table saw. I s...

(Posted by gringoticahouse 11 years ago)

What Is A Sears Electronic 10'table Saw Worth

what is a sears electronic 10" table saw w/ext,& base model 113.290650 worth?, it works great

what is a sears electronic 10" table saw w/ext,& base model 113.290650 worth?, it works great

(Posted by mastercook76 11 years ago)

Need Wiring Diagram For 71/2 Craftman Table Saw-mdl 113.24151

(Posted by darent 12 years ago)