Craftsman 21807 Support Question

Find answers below for this question about Craftsman 21807 - 10 in. Table Saw.Need a Craftsman 21807 manual? We have 1 online manual for this item!

Question posted by djstory09 on September 26th, 2013

Missing Part Tablesaw

if sears sold the product that was sealed and there is a part missing when i put it together why should i have to order pay and wait instead of them opening a box and giving me the part.

Current Answers

Related Craftsman 21807 Manual Pages

Similar Questions

I Need A Rip Fence For This Table Saw How Can I Get One?

need to buy

need to buy

(Posted by tuccilaroo 9 years ago)

Changing Table Saw Motor To 240v

I have a 10" Craftsman table saw model #152221140. Lost the cover to the wiring which has the diagra...

I have a 10" Craftsman table saw model #152221140. Lost the cover to the wiring which has the diagra...

(Posted by mridude 9 years ago)

How To Remove Table Saw Insert In Craftsman Table Saw 21807

(Posted by astalrs 10 years ago)

What Is A Sears Electronic 10'table Saw Worth

what is a sears electronic 10" table saw w/ext,& base model 113.290650 worth?, it works great

what is a sears electronic 10" table saw w/ext,& base model 113.290650 worth?, it works great

(Posted by mastercook76 11 years ago)

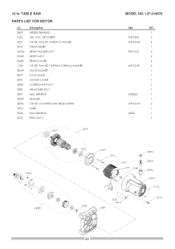

Is A Table Saw Motor From A Model 21807 Compatible With Other Saws?

will the 3HP 15 amp motor from a model 21807 mount properly on a model 137.248880 table saw (both ar...

will the 3HP 15 amp motor from a model 21807 mount properly on a model 137.248880 table saw (both ar...

(Posted by deannarandy 13 years ago)