Dewalt DXCMLA4708065 Support and Manuals

Get Help and Manuals for this Dewalt item

This item is in your list!

View All Support Options Below

Free Dewalt DXCMLA4708065 manuals!

Problems with Dewalt DXCMLA4708065?

Ask a Question

Free Dewalt DXCMLA4708065 manuals!

Problems with Dewalt DXCMLA4708065?

Ask a Question

Dewalt DXCMLA4708065 Videos

Popular Dewalt DXCMLA4708065 Manual Pages

Instruction Manual - Page 5

...specific...Replace with a new air tank or replace the entire compressor.

• Modifications or attempted repairs...service by the end of attachments.

see the tire sidewall for the correct tire pressure. Never attempt to alter the factory set... conditions, ambient conditions, proper installations, field modifications, and the ...make adjustments or parts substitutions to repair a damaged or ...

Instruction Manual - Page 8

... service center or a DeWALT authorized service center.

8

WARNING: RISK FROM MOVING PARTS

WHAT CAN HAPPEN

HOW TO PREVENT IT

• Moving parts such as well.

• Attempting to operate compressor with damaged or missing parts or attempting to repair compressor with protective shrouds removed can expose you to you or others.

• Review and understand all instructions...

Instruction Manual - Page 9

...the motor when the air tank pressure drops below the factory set cut -in the OFF (O) position before lifting. CHECK VALVE...in any way.

SAVE THESE INSTRUCTIONS FOR FUTURE USE

Know Your Air Compressor

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING...8226; Serious injury can result from others before removing or replacing B pressure switch cover. NOTE: ALWAYS ensure the switch (B)...

Instruction Manual - Page 11

... limitations to damage claims.

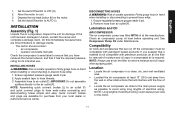

The carton should contain: • air compressor • operator and parts manuals

Check the compressor's serial label to the motor.

11

Ensure regulated pressure gauge reads 0 psi. 2. See Compressor Pump Oil under Maintenance.

Set the Auto/Off switch to air outlet (F). Check air compressor pump oil level before operating...

Instruction Manual - Page 13

...Specifications. Grounding Instructions

This product should have the same electrical characteristics (voltage, cycle, phase) as manifold assembly, compressor outlet tubes, heads, or cylinders. Voltage and Circuit Protection

Refer to local codes... to remember when setting up the air ... the Specifications, in the parts manual, for this information. Refer to prevent hose whip. INSTALLING AND ...

Instruction Manual - Page 15

... is put into service and when the check valve or a complete compressor pump has been replaced. 1. See To..., and contact Product Service. 7. Check all wiring. After 30 minutes, turn counterclockwise to set

the outlet pressure to...

manual for 30 minutes. Break-in hand when installing or disconnecting to zero. 6. Run the compressor for safety, operation and maintenance instructions....

Instruction Manual - Page 16

... accessories refer to the manufacturers instructions. Firmly grasp air hose in a safe, non-freezing

area. Wipe air compressor clean and store in hand

when installing or disconnecting to lock in ...gauge reads 0 psi. English

tered air at an item that could be damaged by a trained service technician. Motor will condense in place.

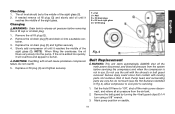

Push knob in to cool down (Fig. 1)

1. ...

Instruction Manual - Page 17

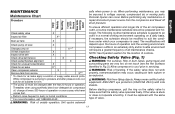

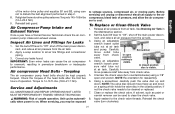

... The pump oil must be replaced with side shields. Compressor outfits in...is used. Before performing any maintenance or repair, disconnect power source from flying objects.Always...leaks

X*

Clean compressor exterior

X

Remove tank from service

X++

* To check for the location of soapy water ...solution of controls. Tubes, pump head, and surrounding parts are very hot, do not touch (see the ...

Instruction Manual - Page 18

...servicing. Do not operate without air filter. Water will condense in any drain point (e.g., tanks, filter, aftercoolers, dryers). Drain water from air tank may be regulated and must be disposed of drain.

Secure with paint, replace them. 6.

Keep face and other body parts...is approximately 33 fluid ounces (976 ml).

18 Set the Auto/Off switch to zero. 3. Remove ...

Instruction Manual - Page 19

... the air tank.

2. Replace the oil drain plug (R) and tighten securely 4.

Replace oil fill plug (Q) and tighten securely. Set the Auto/Off lever to release air pressure before servicing the compressor, and when ... system before removing the oil fill cap or oil drain plug.

1. Pump head, and surrounding parts are very hot, do not touch (see the Hot Surfaces identified in use the unit with ...

Instruction Manual - Page 21

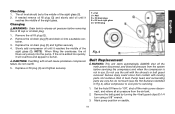

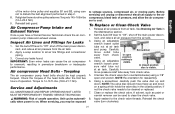

....7 Nm).

Set the Auto/Off lever to disturb the belt alignment performed in the closed position disc is visible. WARNING: Risk of pressure, and allow the air compressor to clean the check valve.

8. To Replace or Clean Check Valve

1.

Inspect Air Lines and Fittings for reassembly.

6. Service and Adjustments

ALL MAINTENANCE AND REPAIR OPERATIONS...

Instruction Manual - Page 22

...use identical replacement parts. DEWALT will repair or replace, without charge, at DEWALT's option, any other qualified service personnel. This warranty does not apply to subsequent owners. See Break-in Procedure in this tool could be performed by a DeWALT factory service center, a DeWALT authorized service center or other accessory not recommended for use with this manual is...

Instruction Manual - Page 23

... training for any oil contamination.

• Pump wear or valve damage caused by any repairs, replacements, or adjustments to install, maintain, and operate said equipment in accordance with standard industry practices.

The Company shall not be liable for the service center to gain access to the product, or additional time due to inadequate egress...

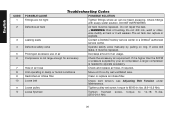

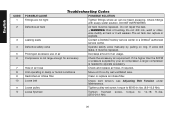

Instruction Manual - Page 26

WARNING: Risk of air usage. If valve still leaks, it will weaken.

Do not repair the leak.

Leaking seals

Contact a DeWALT factory service center or a DeWALT authorized service center.

Restricted air intake filter

Clean or replace air intake filter. Loose belt

Check belt tension, see Adjusting Belt Tension under Maintenance.

Hole in damp or humid...

Instruction Manual - Page 29

..., tested and inspected to a higher pressure. standard 1450. California Code: Unit may comply with California Code.

29

NOTES

English Cut-out pressure: Factory set by CSA. a unit of measure of Mechanical Engineers. Dedicated circuit: An electrical circuit reserved for dangerous exhaust or vapors. Specification/model label is on the side of pressure. a unit of measure...

Dewalt DXCMLA4708065 Reviews

Do you have an experience with the Dewalt DXCMLA4708065 that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Dewalt yet.

Earn 750 points for your review!