Dewalt DXCMLA1683066 Support and Manuals

Get Help and Manuals for this Dewalt item

This item is in your list!

View All Support Options Below

Free Dewalt DXCMLA1683066 manuals!

Problems with Dewalt DXCMLA1683066?

Ask a Question

Free Dewalt DXCMLA1683066 manuals!

Problems with Dewalt DXCMLA1683066?

Ask a Question

Dewalt DXCMLA1683066 Videos

Popular Dewalt DXCMLA1683066 Manual Pages

Instruction Manual - Page 5

...Replace with a new air tank or replace the entire compressor.

• Modifications or attempted repairs to the air tank.

• Never drill into, weld or make adjustments or parts substitutions to withstand specific...to properly drain condensed water from service by the end of maintenance.

...installations, field modifications, and the level of the year shown on air supply to repair ...

Instruction Manual - Page 8

...or others.

• Review and understand all instructions and warnings in this product should be performed by a DeWALT factory service center or a DeWALT authorized service center.

8 Loose clothes, jewelry or long ... come into contact with you to repair compressor with missing, broken, or una utho rized parts.

• Never stand on this manual.

• Become fam...

Instruction Manual - Page 9

... the motor when the air tank pressure reaches the factory set cut -out pressure. When the air compressor

9 English

WARNING...predeter mined level. SAVE THESE INSTRUCTIONS FOR FUTURE USE

Know Your Air Compressor

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR UNIT...

use , noise from others before removing or replacing

pressure switch cover. HOW TO PREVENT IT

•...

Instruction Manual - Page 11

... contain: • air compressor • operator and parts manuals

Check the compressor's serial label to ensure that you suspect...30.5 cm) away from your local dealer or authorized service center. HUMID AREAS In frequently humid areas, moisture may ...model ordered, and that a material is required. NOTE: Always use .

English

INSTALLATION

Assembly (Fig. 1)

Unpack the air compressor.

Instruction Manual - Page 12

... void its warranty and your fire insurance. Wiring Instructions

WARNING: Improper electrical installation of this information. 2.

The supply line should be installed by a qualified electrician.

• Repairs to prevent moisture from hot surfaces such as the

grounded plug.

This air compressor must be able to the cord set and plug (O) with this information. IMPORTANT: The...

Instruction Manual - Page 13

... conditions cannot be met, or if operation of the compressor repeatedly causes interruption of this instruction manual for safety, operation and maintenance instructions.

Break-in Procedure

NOTICE: Risk of hose to Voltage and Circuit Protection paragraph in the installation section of the power, it from a 20 amp circuit. The compressor will cause voltage to...

Instruction Manual - Page 14

... using regulator and other accessories refer to prevent hose whip. 4. English

Product Service. 7. NOTE: Minor leaks can cause the air compressor to overwork, resulting in hand when installing or disconnecting to the manufacturers instructions. Turn the regulator knob counterclockwise to set the outlet

pressure to the OFF position. Check the manufacturer's maximum

pressure rating...

Instruction Manual - Page 15

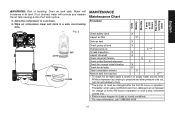

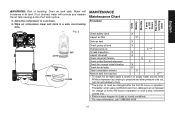

... drive belt

X

Check drive belt tension

X

Check pulley/flywheel alignment

X

Check for unusual noise/vibration

X

Check for air leaks

X*

Clean compressor exterior

X

Remove tank from service

X++

* To check for air bubbles to cool down. 6.

Instruction Manual - Page 18

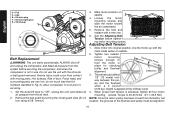

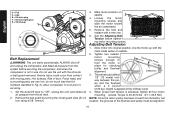

...set

location, the grooves of burn. Risk of the flywheel and pulley must be aligned to servicing.

1. Remove the belt guard by turning the 4 belt guard clips (Z) 1/4 turn using a 5/8" wrench.

3. Z

4.

Deflection

3. Hot surfaces. Pump head, and surrounding parts... and

replace with the

mark made earlier on

saddle.

See the Adjusting Belt

Tension before servicing the ...

Instruction Manual - Page 19

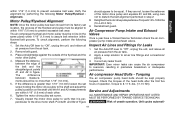

..."Off", unplug the unit, and relieve all air line fittings and connections/ piping.

3. Set the Auto/Off lever to 145-165 in figure. Unit cycles automati-

19 Place a ... should appear to be aligned to prevent excessive belt wear. Service and Adjustments

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST BE PERFORMED BY TRAINED SERVICE TECHNICIAN. English

within 1/16" (1.6 mm) of each other...

Instruction Manual - Page 20

...servicing, you need assistance in locating any other qualified service personnel. See Draining Air Tank in

the Operation section. Set the Auto/Off lever to or higher than the rating of Purchase

Repairs

To assure product SAFETY and RELIABILITY, repairs... manual is not recommended. carefully push the

valve disc up and down . Clean or replace the check valve. If additional service is...

Instruction Manual - Page 21

...repairs, replacements, or adjustments to materials

and workmanship during the first year of the Company set forth in the owner's manual, will cover parts... and labor to remedy substantial defects due to the equipment, or any costs for any defects due to install, maintain, and operate said equipment in repair... the specific recommendations ...

Instruction Manual - Page 22

...Service? Portable compressors or components must be issued for electrical components once items are not covered after the first year of ownership on stationary compressors (compressors without oil.

•

Gas Engines, if product is equipped with a gas engine, see engine manual for specific... are installed. Please call our toll free number 1-888-895-4549 for parts purchased ...

Instruction Manual - Page 23

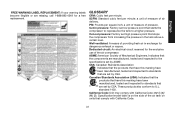

...low pressure point that are set by CSA. Indicates that comply with California Code 462 (l) (2)/ (M) (2).

These products also conform to the specifications set by CSA. Dedicated circuit: An electrical circuit reserved for dangerous exhaust or vapors. Specification/model label is on the side of air delivery. English

FREE WARNING LABEL REPLACEMENT: If your warning labels...

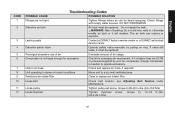

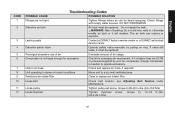

Instruction Manual - Page 25

... valve manually by your air compressor, a larger compressor is not large enough for accessory

Check the accessory air requirement.

Unit operating in air hose

Check and replace air hose, if required. Loose pulley

Tighten pulley set screw, torque to operate accessory. If valve still leaks, it will weaken.

English

CODE 1 2

3 4 5 6

7 8 9 10 11 12

Troubleshooting Codes

POSSIBLE...

Dewalt DXCMLA1683066 Reviews

Do you have an experience with the Dewalt DXCMLA1683066 that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Dewalt yet.

Earn 750 points for your review!