Singer 4411 Heavy Duty Support Question

Find answers below for this question about Singer 4411 Heavy Duty.Need a Singer 4411 Heavy Duty manual? We have 1 online manual for this item!

Question posted by dwdsad on January 25th, 2017

Reverse Caused Nesting?

Current Answers

Answer #1: Posted by Troubleshooter101 on January 25th, 2017 9:34 AM

sewing machine thread bunching up

ANYTIME THE SEWING MACHINE THREAD IS BUNCHING UP, OR BIRD NESTING, ON THE TOP OF YOUR FABRIC, THE CULPRIT HAS SOMETHING TO DO WITH YOUR BOBBIN. HERE ARE SOME THINGS TO CHECK BEFORE CALLING SEWING REPAIR 911:

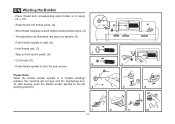

1. IS YOUR BOBBIN THREADED CORRECTLY?

If your machine uses a bobbin case, take the bobbin completely out of the case and re-thread it. Be careful to follow the instructions for your machine, and make sure you have the bobbin thread engaged in the bobbin tension. A good test for this is to hold onto the bobbin thread with one hand. If the bobbin drops all the way to the floor, you missed the tension spring in the bobbin case.

2. IS YOUR BOBBIN CASE TENSION TOO LOOSE?

If you have loosened the screw on your bobbin case to accommodate thicker threads for surface design work, you might not have re-adjusted it correctly for regular thread. After correctly threading the bobbin case, tug gently on the bobbin thread. You should feel some resistance, but the thread should move freely. If you have not made any changes to this tension setting, it is likely not to be the cause of any thread bunches, as it is set correctly at the factory. If you do adjust it, be sure to do so in small increments to avoid dislodging the entire screw.

CONVERSELY, THE REASONS THAT THREAD CAN BUNCH UP UNDERNEATH YOUR FABRIC HAVE ALL TO DO WITH YOUR NEEDLE TENSION.

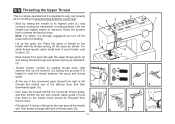

1. IS THE NEEDLE THREAD THREADED CORRECTLY?

Cut the thread a few inches from the spool, and pull it through the needle. Re-thread, taking care to engage the upper thread completely in the tension discs. I always suggest to my students that they hold the thread on either side of the tension disc, and slide it back and forth a bit between the plates with a flossing motion. The tension discs need to "grasp" the thread snugly.

2. IS THE PRESSER FOOT UP?

Duh. We've all done it!

3. IS YOUR MACHINE CLEAN?

Frequent dusting underneath the throat plate and along the thread path will prevent all sorts of stitching and machine problems. Of course, good quality thread, a new, sharp sewing machine needle, and the correct bobbins for your make and model of sewing machine are basic requirements for producing good quality stitches. Frequent dusting, cleaning and oiling will also prevent these and many other stitching problems you might encounter.

Thanks

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful. Please feel free to submit further info for your question, if a solution was not provided. I appreciate the opportunity to serve you!

Troublshooter101

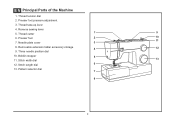

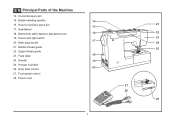

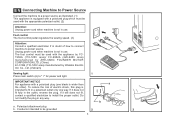

Related Singer 4411 Heavy Duty Manual Pages

Similar Questions

Error message E7 is up on my Singer Stylist model 7258 sewing machine. It is not working at all. I t...

question regarding normal operations.

When sewing the thread under the fabric comes in large loops. The tension wheel of the upper thread ...

My sewing machine will beep and stop sewing after three inches of sewing. I have taken it to be repa...