Singer 4411 Heavy Duty Support Question

Find answers below for this question about Singer 4411 Heavy Duty.Need a Singer 4411 Heavy Duty manual? We have 1 online manual for this item!

Question posted by dwdsad on January 25th, 2017

The Problem Is Specific To Reverse Stitching, It Is Not A General Machine

question regarding normal operations.

Current Answers

Answer #1: Posted by TommyKervz on January 28th, 2017 5:52 AM

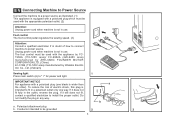

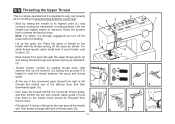

Download and refer to the instructions manual https://www.helpowl.com/manuals/Singer/4411HeavyDuty/179353

Related Singer 4411 Heavy Duty Manual Pages

Similar Questions

Reverse Caused Nesting?

Works fine stitching in forward, when reverse material rolls up and stitching nests. Have new needle...

Works fine stitching in forward, when reverse material rolls up and stitching nests. Have new needle...

(Posted by dwdsad 7 years ago)

How To Tighten Bottom Tension On Heavy Duty 4411 Machine ?

(Posted by Gabyguyer 8 years ago)

Is A Special Foot Required To Free Form Stitch On Singer Sewing Machine Model 55

(Posted by kopitkin 8 years ago)

Reverse Stitch Function Does Not Work

The reverse stitch function does not work. It just continues forward.

The reverse stitch function does not work. It just continues forward.

(Posted by wynakay 10 years ago)