Singer 4411 Heavy Duty Support Question

Find answers below for this question about Singer 4411 Heavy Duty.Need a Singer 4411 Heavy Duty manual? We have 1 online manual for this item!

Question posted by Gabyguyer on October 18th, 2015

How To Tighten Bottom Tension On Heavy Duty 4411 Machine ?

The person who posted this question about this Singer product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Answer #1: Posted by TechSupport101 on October 18th, 2015 5:03 AM

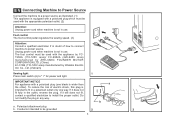

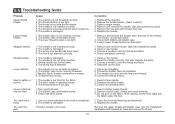

Hi. Page 27 of the Instructions Manual here https://www.helpowl.com/manuals/Singer/4411HeavyDuty/179353 reads:

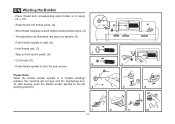

The bobbin tension has been set correctly at the factory, so you do not need to adjust it.

Related Singer 4411 Heavy Duty Manual Pages

Similar Questions

Singer 44s Heavy Duty Sewing Machine

can this machine be installed in a sewing machine cabine

can this machine be installed in a sewing machine cabine

(Posted by Lhcajun2004 3 years ago)

The Problem Is Specific To Reverse Stitching, It Is Not A General Machine

question regarding normal operations.

question regarding normal operations.

(Posted by dwdsad 7 years ago)

Handwheel Clicking Loudly

my 4423 singer heavy duty 'had' thread under bobbin & wouldnt move, i removed that & now the...

my 4423 singer heavy duty 'had' thread under bobbin & wouldnt move, i removed that & now the...

(Posted by sreymahsilalm 7 years ago)

How Do I Fix The Tension On My Singer5523 Machine

(Posted by Fsbsc1 9 years ago)

Singer 4411

mi singer 4411 sewing manchine, doesnt pick up thret from this bobbin, because this needs bar need a...

mi singer 4411 sewing manchine, doesnt pick up thret from this bobbin, because this needs bar need a...

(Posted by jmdlr10472 10 years ago)