Ridgid MS255SR Support Question

Find answers below for this question about Ridgid MS255SR.Need a Ridgid MS255SR manual? We have 1 online manual for this item!

Question posted by amazingwoodflooring on December 12th, 2015

Saw Blade Stops On Cut

why does mitter saw blade stop in the middle of the cut

Current Answers

Answer #1: Posted by TommyKervz on December 13th, 2015 3:34 AM

See possible reasons here https://ca.answers.yahoo.com/question/index?qid=20070919175219AA1AVpj

Related Ridgid MS255SR Manual Pages

Similar Questions

Ms255sr Ridgid Miter Saw Fence

Hi, I am looking for the fence for the MS255SR. It has been difficult to find the part number. If I ...

Hi, I am looking for the fence for the MS255SR. It has been difficult to find the part number. If I ...

(Posted by jqjrpr 1 year ago)

Why Is The Saw So Slow, The Model Is Ms255sr

Why is my saw so slow m

Why is my saw so slow m

(Posted by cgarcilazo1 3 years ago)

Ridgid Ms255sr 'inner Screw'

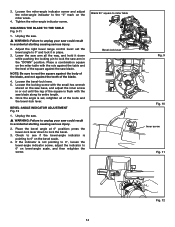

I have the Ridgid ms255sr and can't find the "inner screw" (fig 10) http://www.homedepot.com/catalog...

I have the Ridgid ms255sr and can't find the "inner screw" (fig 10) http://www.homedepot.com/catalog...

(Posted by doug29112 8 years ago)

How To Repai The Rails For Cutting Table On A 10' Ridgid Tile Saw Model# R4010

(Posted by MOTODAD 10 years ago)

Metal Cutting Bandsaw Blade

Just bought a used RIDGID BS14000 bandsaw, has a wood blade on it, but I want to cut metal. Need to ...

Just bought a used RIDGID BS14000 bandsaw, has a wood blade on it, but I want to cut metal. Need to ...

(Posted by DavidYork 10 years ago)