Hitachi c8fb2 Support Question

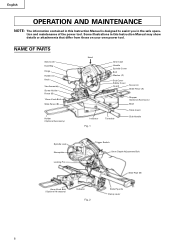

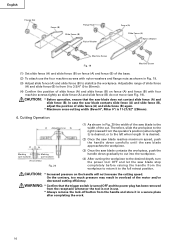

Find answers below for this question about Hitachi c8fb2 - 998866 Extension Guide Wing Assembly.Need a Hitachi c8fb2 manual? We have 1 online manual for this item!

Question posted by jhraley on October 7th, 2012

How Do I Pull The Motor Stator To Replace The Bearings?

My C8FB2 bearing are shot from brick dust. I have the new bearings and the motor housing off but can't pull the stator off to replace the rear bearings.

Current Answers

Answer #1: Posted by hzplj9 on October 14th, 2012 9:18 AM

If you have the motor out of the casing then you need to heat the bearing housing to enable it to come off of the shaft. It has been 'sweated' on at the factory so it is a tight fit. Not an easy task I'm afraid. The aid of a bearing puller around the bearing would help once heated. I would suggest googling the internet for 'how to remove a tight bearing' for example and you should be able to get the right information.

Related Hitachi c8fb2 Manual Pages

Similar Questions

Dimensions Or Replacement For Fence Slides

Hello. Can you give me the dimensions or an alternative for the sliding fence assembly?

Hello. Can you give me the dimensions or an alternative for the sliding fence assembly?

(Posted by nissa783 2 years ago)

Screeching Noise

nail gun gives screeching noise when firing nails sounds like fan motor but not sure when activated ...

nail gun gives screeching noise when firing nails sounds like fan motor but not sure when activated ...

(Posted by Rongowrie 2 years ago)

C10fs Compound Miter Saw Bearing Replacement

how do I remove the bearing from the armature

how do I remove the bearing from the armature

(Posted by Bobster8820 3 years ago)

Can I Replace My Old Ni Cad Batteries With Some Lithium Ones.

(Posted by jamessmartcarpentry 11 years ago)

Bandsaw Replacement Guides

my band saw guides have worn out can i buy new guides without having to replace the whole assembly.

my band saw guides have worn out can i buy new guides without having to replace the whole assembly.

(Posted by davidkeniston 12 years ago)