Hitachi c8fb2 Support Question

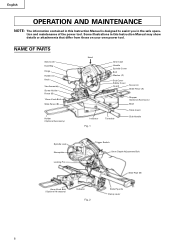

Find answers below for this question about Hitachi c8fb2 - 998866 Extension Guide Wing Assembly.Need a Hitachi c8fb2 manual? We have 1 online manual for this item!

Question posted by nissa783 on November 6th, 2021

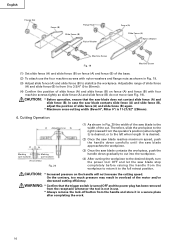

Dimensions Or Replacement For Fence Slides

Hello. Can you give me the dimensions or an alternative for the sliding fence assembly?

Current Answers

Answer #1: Posted by SonuKumar on November 7th, 2021 8:52 AM

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Hitachi c8fb2 Manual Pages

Similar Questions

I Require A Vise Assembly For A Hitachi C8fse Slide Compound Saw, Please Help

I have an Hitachi C8FSE Slide Compound Saw and wish to purchase a Vise Assembly, can anybody help?

I have an Hitachi C8FSE Slide Compound Saw and wish to purchase a Vise Assembly, can anybody help?

(Posted by davaki 10 years ago)

How Do I Pull The Motor Stator To Replace The Bearings?

My C8FB2 bearing are shot from brick dust. I have the new bearings and the motor housing off but can...

My C8FB2 bearing are shot from brick dust. I have the new bearings and the motor housing off but can...

(Posted by jhraley 11 years ago)

The Chuck On My Dh30pc2 Now Longer Grabs The Drill , Do I Need To Replace ?

the chuck on my DH30PC2 now longer grabs the drill bits, do I need to replace the whole thing and ho...

the chuck on my DH30PC2 now longer grabs the drill bits, do I need to replace the whole thing and ho...

(Posted by colinhsmith 11 years ago)

Can I Replace My Old Ni Cad Batteries With Some Lithium Ones.

(Posted by jamessmartcarpentry 11 years ago)

Bandsaw Replacement Guides

my band saw guides have worn out can i buy new guides without having to replace the whole assembly.

my band saw guides have worn out can i buy new guides without having to replace the whole assembly.

(Posted by davidkeniston 12 years ago)