Dewalt D55154 Support Question

Find answers below for this question about Dewalt D55154.Need a Dewalt D55154 manual? We have 2 online manuals for this item!

Question posted by jatimreg on October 11th, 2021

How To Change The Oil For D5514 Compressor

The person who posted this question about this Dewalt product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Answer #1: Posted by SonuKumar on October 12th, 2021 1:35 AM

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

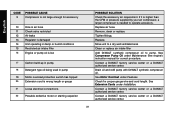

Related Dewalt D55154 Manual Pages

Similar Questions

Piston Rings Keep Blowing Out.

I have a Dewalt D55146 air compressor and it wouldnt build pressure. First i replced the inlet check...

I have a Dewalt D55146 air compressor and it wouldnt build pressure. First i replced the inlet check...

(Posted by flowersjason537 9 months ago)

D55154 Air Compressor

My compressor runs, tank pressure gauge says 130, compressor won't cut out and tank has no air

My compressor runs, tank pressure gauge says 130, compressor won't cut out and tank has no air

(Posted by stevenjardine5 3 years ago)

How To Change Brushes On Dewalt D55146 Type 4 Air Compressor?

looking for precise instructions on changing the brushes on a Dewalt D55146 type 4 air compressor. I...

looking for precise instructions on changing the brushes on a Dewalt D55146 type 4 air compressor. I...

(Posted by randy30400 9 years ago)

D55146 How To Change Oil.

D55146 Manual Talks Of Changing Oil How Is That Done?

D55146 Manual Talks Of Changing Oil How Is That Done?

(Posted by dagresta 11 years ago)