Brother International DB2-B737 Support Question

Find answers below for this question about Brother International DB2-B737.Need a Brother International DB2-B737 manual? We have 2 online manuals for this item!

Question posted by karen10712 on July 11th, 2014

Needle Only Moves Up And Up Won't Sew

my needle will only sew up and down it won't move, I have just moved it and I'm wondering if I may of knocked something or is there a lever to make it darn

Current Answers

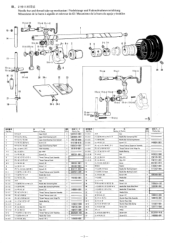

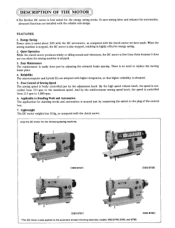

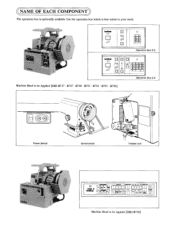

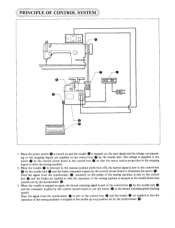

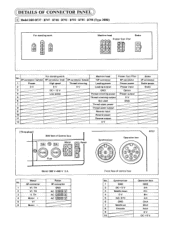

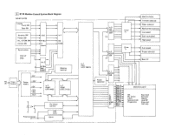

Related Brother International DB2-B737 Manual Pages

Similar Questions

Hi I Have An Industrial Sewing Machine Db2-b797 Which Has Served For 30 Years'

have trouble thread bunching on needle, breaking on reverse,only needle plate replacements occasiona...

have trouble thread bunching on needle, breaking on reverse,only needle plate replacements occasiona...

(Posted by bola79344 8 years ago)

Machine Foot Fault

I Hope You Can Help, I Have A Brother Exedra DB2-B737 413 Industrial Sewing Machine And The Foot Is ...

I Hope You Can Help, I Have A Brother Exedra DB2-B737 413 Industrial Sewing Machine And The Foot Is ...

(Posted by Bvneeson 9 years ago)

Brother Sewing Machine Db2-b737 Price In Bangalore ,india

brother sewing machine db2-b737 price in Bangalore ,india

brother sewing machine db2-b737 price in Bangalore ,india

(Posted by prakashbansal2006 10 years ago)

I Go To Sew A Button Hole It Says Lower Buttonhole Lever 1 And I Don't Understan

i go to sew a button hole it says lower buttonhole lever 1 and i don't understand what they want cau...

i go to sew a button hole it says lower buttonhole lever 1 and i don't understand what they want cau...

(Posted by victoryrocks 10 years ago)

What Size Needle Does The Brother Exedra Db2-b737-413 Use?

(Posted by kerri63386 10 years ago)