Brother International BAS-416 Support Question

Find answers below for this question about Brother International BAS-416.Need a Brother International BAS-416 manual? We have 13 online manuals for this item!

Question posted by kjohnson1e11 on January 31st, 2021

Presser A Foot On A Bas 416

Current Answers

Answer #1: Posted by Odin on February 1st, 2021 11:05 AM

If the issue persists or if you require further advice--or if the instructions don't seem to apply--you may want to consult the company: use the contact information at https://www.contacthelp.com/brother%20international/customer-service.

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

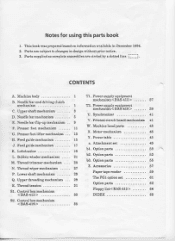

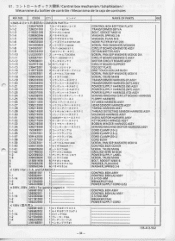

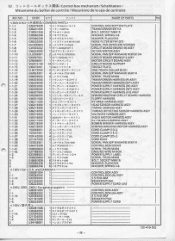

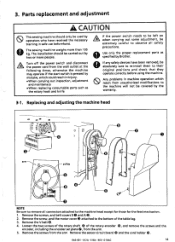

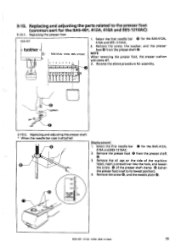

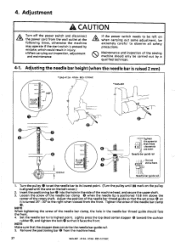

Related Brother International BAS-416 Manual Pages

Similar Questions

The needles on my brother bas416 industrial embroidery machine will not move up and down. How can I ...

Needle bar cushion replacement parts for bas 416