Ryobi DP121L Support and Manuals

Get Help and Manuals for this Ryobi item

View All Support Options Below

Free Ryobi DP121L manuals!

Problems with Ryobi DP121L?

Ask a Question

Free Ryobi DP121L manuals!

Problems with Ryobi DP121L?

Ask a Question

Most Recent Ryobi DP121L Questions

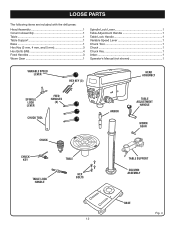

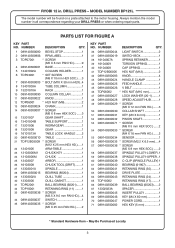

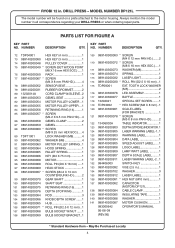

I Am Looking For A Part For The Ryobi 12 In. Drill Press W/ Laser Model Dp121l

My name is Carlos Alvarez, from Mexico, and I'm looking for part 27. 13303001A SPINDLE. Can you help...

My name is Carlos Alvarez, from Mexico, and I'm looking for part 27. 13303001A SPINDLE. Can you help...

(Posted by alvarezmc 2 years ago)

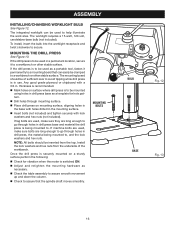

How Do You Adjust The Lazer On The Ryobi Dp121l Drill Press?

(Posted by rtrobaugh 9 years ago)

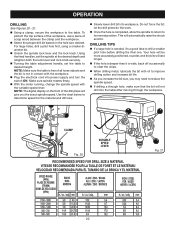

How To Use Ryobi Drill Press Dp121l

(Posted by Bmorma 10 years ago)

Depth-set Operation

It does not working properly. It is either overtighten or not tight enough.

It does not working properly. It is either overtighten or not tight enough.

(Posted by dntxprt 11 years ago)

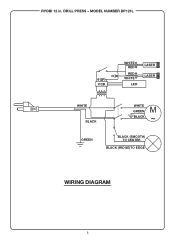

I Had To Put A New Switch On My Dp121l But Take Notice Of What Wire Went Where.

Is the a diagram for the wireing.

Is the a diagram for the wireing.

(Posted by edwardrecker 12 years ago)

Popular Ryobi DP121L Manual Pages

Ryobi DP121L Reviews

We have not received any reviews for Ryobi yet.