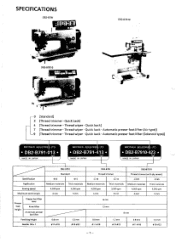

Brother International DB2-B791 Support and Manuals

Get Help and Manuals for this Brother International item

View All Support Options Below

Free Brother International DB2-B791 manuals!

Problems with Brother International DB2-B791?

Ask a Question

Free Brother International DB2-B791 manuals!

Problems with Brother International DB2-B791?

Ask a Question

Most Recent Brother International DB2-B791 Questions

Is There A Separate Manual For The Db2-b791-405?

(Posted by STARLINER 9 years ago)

Popular Brother International DB2-B791 Manual Pages

Brother International DB2-B791 Reviews

We have not received any reviews for Brother International yet.