Singer 9970 Support Question

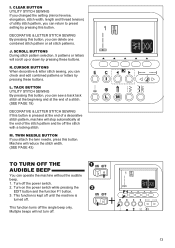

Find answers below for this question about Singer 9970.Need a Singer 9970 manual? We have 1 online manual for this item!

Question posted by alewis41 on November 18th, 2016

Why Won't My Machine Sew, Checked Bobbin And Retreaded. Has Power Just Will Not

Current Answers

Answer #1: Posted by Troubleshooter101 on January 23rd, 2017 10:09 PM

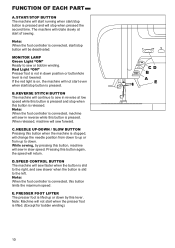

With the manual on hand along with the following tips, many of the most common sewing problems can be resolved.

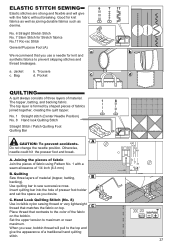

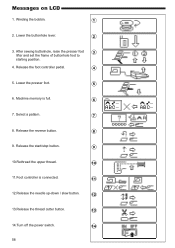

1. Machine Not SewingIf the machine is simply not sewing or has other related errors, the easiest thing to check is whether the thread and needle are set up properly.

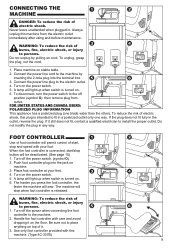

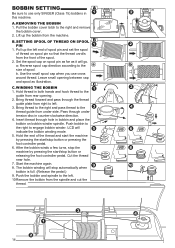

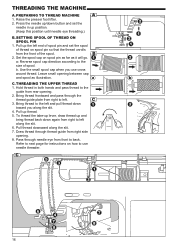

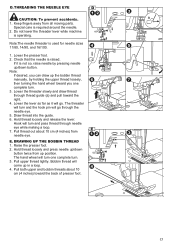

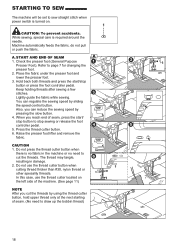

Threading the MachineCheck that the machine is threaded properly according the manual. When threading the machine, remember to always do so with the presser foot up, which releases the tension. Once threaded, putting the presser foot down will apply tension to the thread.

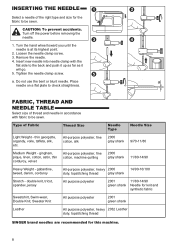

Sewing Machine NeedleBe sure that the needle is locked and facing the correct direction for the machine. If it's not, the thread will not be picked up by the hook when sewing. The flat side of the needle shank faces away from the bobbin insertion point in most machines. Blunt or damaged needles can contribute to a number of sewing problems, so don't wait until the needle is broken to change it.

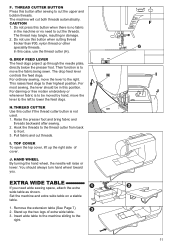

Fabric Not Feeding or Is JammingBoth the presser foot and feed dog may have raise and lower settings. Without enough pressure on the fabric from the presser foot, the feed dog cannot do its job. On the other hand, having the presser foot too low may cause too much pressure or prevent the fabric from feeding through, causing jams. Check that the feed dog is in its raised position when sewing. If the feed dog seems to be jammed, it may be due to lint and debris.

2. Breaking NeedlesThe needle is often the easiest part of a sewing machine to change; that's fortunate because it is also the part most prone to wear. Needles may break due to simple reasons like prolonged use or hitting a straight pin; these breaks can be difficult to predict. However, needles also break from very controllable factors such as forcing the fabric through the feed or by using the wrong needle. Forcing the fabric rather than allowing the feed dog to do its job can bend or break the needle; a bent needle may hit the hook when sewing, which can lead to broken needles and damage to the hook.

Using the wrong size needle is often the culprit of a broken needle. Needle size should be relative to the thickness of the material being sewn. American needle sizes range from 8-19 while European sizes range from 60-120. Needles will often be listed with both sizes, such as 70/10. There are also specialty needles for fabrics such as leather and denim.

Skipped stitches are usually due to a bad needle. The needle may have become damaged or bent by sewing material too thick for the needle, forcing material through the feed dog, or hitting a straight pin. If the problem seems to be consistently reoccurring, it may be due to forcing the fabric. Sewers should allow the feed dog to pull the fabric and only use their hands to guide the fabric through the feed. When sewing knitted fabrics, using a stretch needle can help prevent skipped stitches.

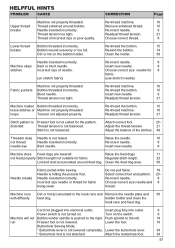

4. Sewing Machine Thread Is Tangling, Bunching, or BreakingHaving the thread not cooperate as intended is a problem that can lead to stress among those who sew. The good news is that thread problems usually arise from very fixable issues.

Thread Looping and BunchingThread looping problems that occur on the bottom side of the fabric are typically issues with the upper threading, not the bobbin threading. Looping or bunching that occurs on top of the fabric tends to a problem with the bobbin threading. For any thread issue, it's best to begin by checking that the machine is threaded properly according to the machine's specifications. If the machine was not threaded with the presser foot up, it will not have the needed tension for sewing. Also check that there is no lint or debris in the area and that moving parts are oiled. Finally, check the needle for any damage.

Thread BreakingThread that continually breaks may be an issue with the quality of the thread or obstructions within the machine. Inexpensive, bargain threads typically shed more lint, contain knots, and break more often than good, quality threads. Lint and knots can obstruct the thread from feeding through the machine. Also check the path the thread travels through, including the bobbin and needle, is free from burrs, nicks, or any sharp points that may cause a break or snag. Polish these areas with sand paper or steel wool. If the spool itself seems to be jamming, try changing the direction from which the spool is unwinding. Some fine threads used for embroidery may be more prone to breakage; it is best to use a specified embroidery needle for these projects.

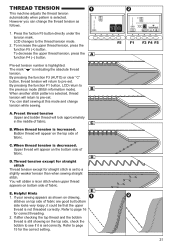

Tension AdjustmentsMost sewing machines require very little altering of the tension settings or disks. However, if all other thread issues have been resolved but the problem is still reoccurring, not having proper tension may be the problem. Changing the tension can affect the timing of the machine as the pressure exerted on the upper thread and bobbin thread needs to be even; therefore, its best to review the machine's manual for tension specifications. Upper tension is user adjustable, but the setting should be in a medium range for most sewing projects. Tension problems with the bobbin threading are particularly intricate and should be repaired professionally. Using different color threads in the upper threading and bobbin is a good way to determine which area is having tension problems.

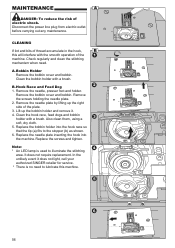

5. Mechanical Noises and MaintenanceIf the sewing machine is making uncommon noises, such as grinding or banging, the machine parts may be jammed or in need of cleaning or maintenance. Do not use the machine when it is operating this way, and turn off power to the machine before inspecting the issue. Lint buildup will occur due to the constant use of fabric and thread. Clean lint and other debris out of the machine using a brush.

The machine should be oiled according the owner's manual. Only sewing machine oil should be used to lubricate moving parts. The oil prevents wear as well as rust. Run a test thread and fabric through the machine to remove excess oil.

Examine the machine for loose screws and tighten them. However, do not tighten hex screws as these screws often affect the timing and settings of the machine. If any of hex screws seem to be missing or out of order, the machine should be taken to a professional for repairs.

Regular cleaning and maintenance can help protect the machine for future use, but if mechanical noises still continue, the machine should be examined by a professional repairman.

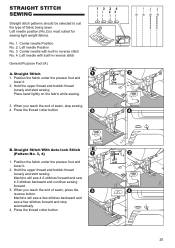

While not necessarily a problem with the machine, some might question why the seams they sew look more homemade than professional or why pattern pieces don't fit together. A number of factors could be the culprit here. If there are large holes in the stitches, the needle is too big for the fabric. Ironing or steaming the fabric before sewing is also a must for a professional-looking end product. To accurately sew seams, it is important to watch the seam guide rather than the needle. Using the guide will keep the seams consistent and balanced throughout the project, which will allow pattern pieces to properly fit together.

Finding Sewing Machine Parts on eBayWhen problems arise with machine parts, needles, and thread, replacements can be found on eBay. From the eBay homepage, the Sewing & Fabric subcategory can be located by clicking on Home, Outdoors & Decor in the category menu and proceeding to the Crafts category. From here, users can browse or search for sewing machine needles, oil, and other parts and supplies as well as quality thread and fabric..

ConclusionMany common sewing issues can be resolved within the maintenance and setup of the machine. However, if any of the troubleshooting tips do not resolve the problems, it is always best to take the machine in for professional repairs and inspection, especially if it seems to be a timing or tension issue. Continued use of the machine may result in more wear and tear on the machine, which could make the machine completely inoperable. This could lead to expensive repairs or the need to purchase a new sewing machine..

Thanks

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful. Please feel free to submit further info for your question, if a solution was not provided. I appreciate the opportunity to serve you!

Troublshooter101

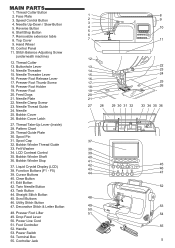

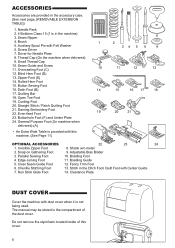

Related Singer 9970 Manual Pages

Similar Questions

I bought the sewing machine during the pandemic and would like to learn how to use it- functions, st...

I am having a problem with the top thread catching on the bobbin case and breaking the thread. I had...

had it in repair shop twice,replace bobbing case twice. it wont sewing. power on but wont sew.