Ryobi RTS10 Support Question

Find answers below for this question about Ryobi RTS10.Need a Ryobi RTS10 manual? We have 4 online manuals for this item!

Question posted by lance4341 on June 5th, 2017

Can't Raise / Lower Saw Blade

Current Answers

Answer #1: Posted by hzplj9 on June 6th, 2017 3:02 AM

https://www.manualslib.com/manual/682212/Ryobi-Rts10.html

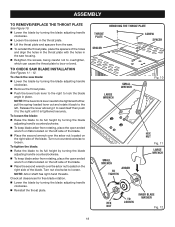

Page 29 of 42 refers to a locking lever which has to be released before you can move the height. It would be worth checking underneath (which should be accessible after removing the bottom cover, if fitted) to see that the slot the blade assembly runs in is not coked up with wood dust etc. Remove power before carrying out these adjustments. Cleaning only but not oiling as oil will attract dust. The manual also gives instructions for assembly and sis-assembly is the reverse.

Hope that solves your dilemma.

Related Ryobi RTS10 Manual Pages

Similar Questions

Hello. There are 2 screws that go through a plate involved in raising and lowering the blade. One is...

I just got a new table saw and cannot raise the saw blade height. please help.