Ryobi RTS10 Support Question

Find answers below for this question about Ryobi RTS10.Need a Ryobi RTS10 manual? We have 4 online manuals for this item!

Question posted by chanburn on March 8th, 2020

Replacing Motor- How Do I Replace The Motor? Have New Motor & Can't Get Housing

How do I get the motor housing off so can replace motor? Have removed two screws (each about 3" long) and gently pried using screwdriver but housing only moves about 1/8 "

Current Answers

Answer #1: Posted by hzplj9 on March 8th, 2020 3:10 PM

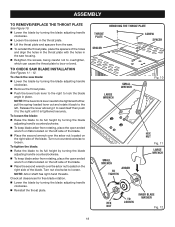

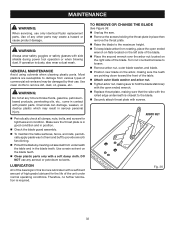

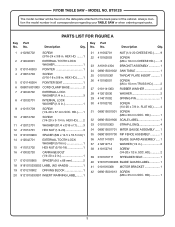

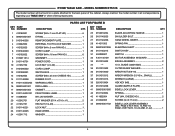

If you go to the manual owl manual link and search for the RTS10 there are 4 manuals available. The 4th one in the list is the repair manual which gives exploded views of the saw. From that it should be possible to identify which parts need to be removed. There is also a circuit diagram with the wiring info so you can verify the correct connections if your motor differs from the original.

Link below:

https://www.helpowl.com/manual.php?file=5202f9c2ed0343867a5d1be5a0d4d119&manual=202346

Hope that helps.

Related Ryobi RTS10 Manual Pages

Similar Questions

Can I Buy A Replacement Motor For My P560?

I want to know if I can buy the motor or find the part # for it? P560 pruner

I want to know if I can buy the motor or find the part # for it? P560 pruner

(Posted by aarngrn 2 years ago)

Ryobi P320 Stopped Working

the lights blink and does not fire.I used it a week before and it worked fine. Now nothing.Replaced ...

the lights blink and does not fire.I used it a week before and it worked fine. Now nothing.Replaced ...

(Posted by bigbaseshop 7 years ago)

Replacement Of Pad.on A Ryobi Rst #10 Table Saw.

The pad is located behind the knob that locks the blade swivel.

The pad is located behind the knob that locks the blade swivel.

(Posted by tabucher 11 years ago)