Ryobi RTS10 Support Question

Find answers below for this question about Ryobi RTS10.Need a Ryobi RTS10 manual? We have 4 online manuals for this item!

Question posted by ricosflooring03 on June 23rd, 2015

How Do I Remove The Height Wheel On My Rst10 Table Saw?

The person who posted this question about this Ryobi product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Answer #1: Posted by TechSupport101 on June 24th, 2015 7:34 AM

See a similar support question here http://www.ereplacementparts.com/ryobi-rts10-table-saw-parts-c-7931_7954_158276.html for assistance with removing the hand wheel.

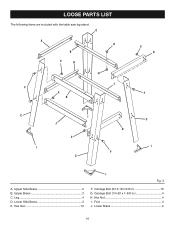

Related Ryobi RTS10 Manual Pages

Similar Questions

Ryobi 10" Table Saw Dado Throat Plate

where can I find a dado throat plate for the Ryobi 10" table saw?

where can I find a dado throat plate for the Ryobi 10" table saw?

(Posted by Rick52757 2 years ago)

Wiring Diagram For Ryobi Rts21 Table Saw Switch

I need to view the wiring diagram for the switch on the Ryobi RTS21 table saw. I had to disconnect t...

I need to view the wiring diagram for the switch on the Ryobi RTS21 table saw. I had to disconnect t...

(Posted by wolfsonjames 9 years ago)

Dado Blade Insert For A Ryobi Rts10 Table Saw

Where can I purchase a dado blade insert for my Ryobi RTS10 10" table saw? I am having difficulty fi...

Where can I purchase a dado blade insert for my Ryobi RTS10 10" table saw? I am having difficulty fi...

(Posted by bstilton 9 years ago)

Will A Ryobi Table Saw Model Rts10 Accept A Dado Blade

(Posted by arivegregon 9 years ago)