Ryobi RB101 Support Question

Find answers below for this question about Ryobi RB101.Need a Ryobi RB101 manual? We have 3 online manuals for this item!

Question posted by robertk49610 on April 7th, 2024

How Do I Replace The Pad Assembly?

Current Answers

Answer #1: Posted by hzplj9 on April 8th, 2024 12:57 PM

https://www.manualowl.com/p/Ryobi/RB101/Manual/111252

There are often simple ways to repair equipment and by looking for fixing screws around the lower part under the foam pad may give you a clue. You may need a Torx screwdriver to undo any screws rather than a cross head.

Hope that solves your problem. Please mark as helpful if it leads you to a satisfactory solution.Thank you.

Answer #2: Posted by SonuKumar on April 9th, 2024 9:10 AM

Instructions:

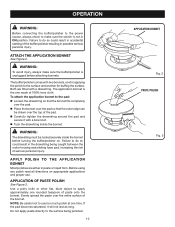

Safety First: Unplug the sander for complete safety.

Remove the Old Pad: The pad is typically held in place by small tabs or by a hook-and-loop (Velcro-like) system. Look at how the old pad is attached and gently remove it.

Inspect the Area: Clean any debris or buildup where the pad mounts.

Install the New Pad:

Tabs: Align the tabs of the new pad with the grooves on the sander base.

Hook-and-Loop: Press the new pad firmly against the sander base.

Check Securely: Ensure the pad is seated correctly and won't slip during operation.

Things to Note:

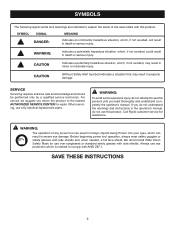

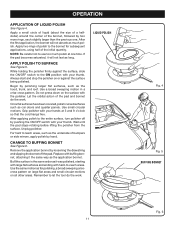

Specific Model: Slight variations may exist for different model numbers. Your owner's manual, if available, would have the most accurate instructions.

Ordering the Pad: Make sure you get the exact replacement pad for your sander model. They are usually available online or at stores carrying Ryobi tools.

Helpful Resources

YouTube Video: Search for "Ryobi RB101 pad replacement" on YouTube. Many handy tutorials exist. Here's one example: https://www.youtube.com/watch?v=inuSHV7KTyk

Manufacturer Website: Visit Ryobi's website and search for your specific model. They may have instructions or diagrams available.

Replacement Parts Websites: Stores specializing in tool replacement parts often carry detailed diagrams and descriptions for the pad assembly.

Let me know if you can't find your specific model, and I'll help search for the right resources!

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Ryobi RB101 Manual Pages

Similar Questions

How to replace drive assembly? Drive plate wornout

I need a replacement battery for my Ryobi model HP41L. Can you provode or direct men to where to pur...

The pad is located behind the knob that locks the blade swivel.

The covers that are included with the RB101 should be tied on once they are properly installed on th...