Ridgid R4030 Support Question

Find answers below for this question about Ridgid R4030.Need a Ridgid R4030 manual? We have 1 online manual for this item!

Question posted by luisgc2229 on December 9th, 2015

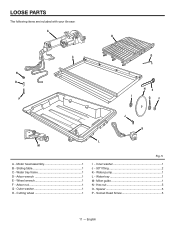

Replacement Of The Brush In The Motor?

Where can I find the brushes for the motor.

Current Answers

Related Ridgid R4030 Manual Pages

Similar Questions

I Need The Part Number For The Motor.

please supply part number for new motor. Mine is smoked. Thank you

please supply part number for new motor. Mine is smoked. Thank you

(Posted by Jeffreyintenzo 5 months ago)

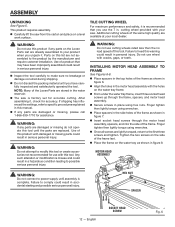

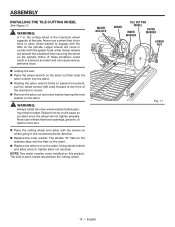

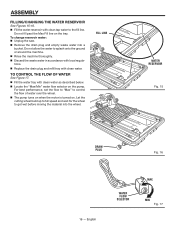

Assembly Motor

Do Rigid grinders have a lifetime warranty. They no longer make my grinder R1005 and needs a new ass...

Do Rigid grinders have a lifetime warranty. They no longer make my grinder R1005 and needs a new ass...

(Posted by jeffhudec13 1 year ago)

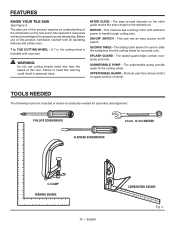

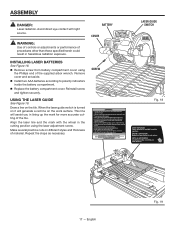

How Do You Replace The Laser Battery?

The laser on my Ridgid R4030 has gone out. How should I go about replacing it?

The laser on my Ridgid R4030 has gone out. How should I go about replacing it?

(Posted by Phat56007 3 years ago)

How Do I Change Brushes

How do I change the motor brushes on a Ridgid R4030S tile saw

How do I change the motor brushes on a Ridgid R4030S tile saw

(Posted by dennis45227 8 years ago)