Ridgid R350CHE Support Question

Find answers below for this question about Ridgid R350CHE.Need a Ridgid R350CHE manual? We have 2 online manuals for this item!

Question posted by jeffyoungrmt on May 10th, 2019

Auto Actuation Not Functional

Current Answers

Answer #1: Posted by Odin on May 10th, 2019 6:32 AM

- Verify adequate air supply

- Lubricate tool

- Install Overhaul Kit

If the issue persists or if you require further explanation, you'll have to consult Ridgid: use the contact information at https://www.contacthelp.com/ridgid/customer-service.

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

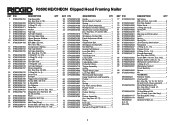

Related Ridgid R350CHE Manual Pages

Similar Questions

gun was working fine then stopped shooting nails the gun is not jammed the slide won't go all the wa...

My KJ 3100 won't start after several attempts it's bin working for a month but trying to start up no...

I have connect Ted the 4 wires but keep tripping the breaker. Must have one wire wrong and through o...

how can we order a replacement motor for the tool. the end has come off part way and the tool in una...

I can't fine in the operators manual for my r350che that part that tells me how to adj. the pres. On...