Ridgid MS255SR Support Question

Find answers below for this question about Ridgid MS255SR.Need a Ridgid MS255SR manual? We have 1 online manual for this item!

Question posted by dawnblckmr on June 21st, 2015

Why Isnt It Slidding Back And Forth Anymore?

De are trying yo use our Ridgid MS255SR to cut slidding back and forth again but we cant get it to unlock, help please!!!!

Current Answers

Answer #1: Posted by TechSupport101 on June 21st, 2015 10:54 PM

Kindly complete and submit the form here for the best advise on your issue.

Related Ridgid MS255SR Manual Pages

Similar Questions

Ms255sr Ridgid Miter Saw Fence

Hi, I am looking for the fence for the MS255SR. It has been difficult to find the part number. If I ...

Hi, I am looking for the fence for the MS255SR. It has been difficult to find the part number. If I ...

(Posted by jqjrpr 1 year ago)

Ms255sr Parts

can you tell me where i can buy parts for my saw please ?

can you tell me where i can buy parts for my saw please ?

(Posted by rjsautoservice 7 years ago)

I Brought Ms255sr From A Action . Looks New . The Motor Runs Very Slow And No Po

Moter runs very slow and has no power & does not speed up ms255sr . Is there any fuse or relay d...

Moter runs very slow and has no power & does not speed up ms255sr . Is there any fuse or relay d...

(Posted by Cep3pal 8 years ago)

Ridgid Ms255sr 'inner Screw'

I have the Ridgid ms255sr and can't find the "inner screw" (fig 10) http://www.homedepot.com/catalog...

I have the Ridgid ms255sr and can't find the "inner screw" (fig 10) http://www.homedepot.com/catalog...

(Posted by doug29112 8 years ago)

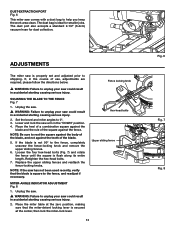

Ridgid Ms255sr Bevel Problems

Hi there please help me to solve my saw bevel problem i have follow all the steps to adjust the beve...

Hi there please help me to solve my saw bevel problem i have follow all the steps to adjust the beve...

(Posted by pm24h 9 years ago)