Ridgid EB4424 Support Question

Find answers below for this question about Ridgid EB4424.Need a Ridgid EB4424 manual? We have 1 online manual for this item!

Question posted by roalsenl on January 13th, 2023

My Eb 44242 Oscillating Sander Won't Start

The person who posted this question about this Ridgid product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Answer #1: Posted by SonuKumar on January 13th, 2023 7:25 PM

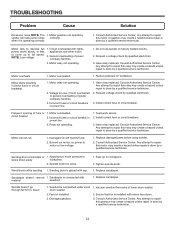

https://www.manualslib.com/manual/801042/Ridgid-Eb4424.html?page=23#manual

https://www.youtube.com/watch?v=VDG2yCopOFI

https://www.youtube.com/watch?v=vk3Td3qxJXA

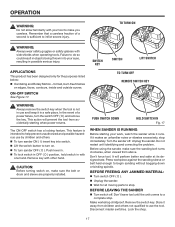

Belt issue or motor issue or power switch

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Answer #2: Posted by Odin on January 13th, 2023 5:59 PM

See Motor will not run at https://www.manualslib.com/manual/801042/Ridgid-Eb4424.html?page=23&term=trouble&selected=1#manual.

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

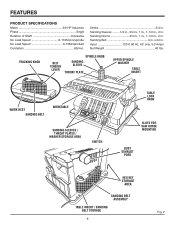

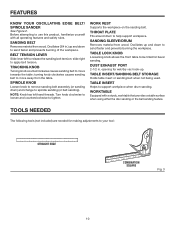

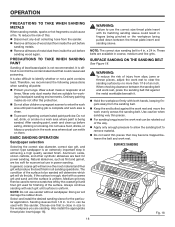

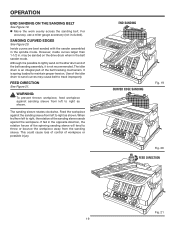

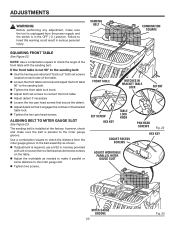

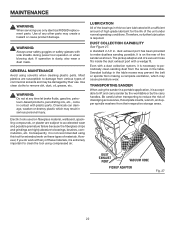

Related Ridgid EB4424 Manual Pages

Similar Questions

I Have The Ridgid Eb44242

I'm missing the three washers that sit above the throat plate washers. Could you tell me what the OD...

I'm missing the three washers that sit above the throat plate washers. Could you tell me what the OD...

(Posted by MWGM99RI 1 year ago)

How To Replace Drive Roller In Ridgid R2740 Belt Sander

How to replace drive roller in ridgid r2740 belt sander. I have the sander disassembled but cannot f...

How to replace drive roller in ridgid r2740 belt sander. I have the sander disassembled but cannot f...

(Posted by Jerrydee49071 3 years ago)

Rigid Spindle Sander Manual Changing The Belt To A Simple Spindle Sander.

Can't seem to locate my manual and want to change the belt configuration to a simple single spindle ...

Can't seem to locate my manual and want to change the belt configuration to a simple single spindle ...

(Posted by evace109 8 years ago)

When I Start It It Just Turns Off

I have a green light when i switch it on but when i start it it just turns off?

I have a green light when i switch it on but when i start it it just turns off?

(Posted by thomas20792 8 years ago)

Where Can I Purchase A Spindle Knob For The Rigid Belt Sander For Eb 44242

(Posted by johncrausen 10 years ago)