Ridgid 100-B Support Question

Find answers below for this question about Ridgid 100-B.Need a Ridgid 100-B manual? We have 1 online manual for this item!

Question posted by thomas20792 on October 13th, 2015

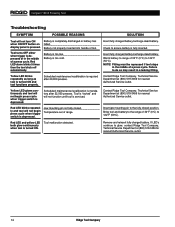

When I Start It It Just Turns Off

Current Answers

Answer #1: Posted by TommyKervz on October 14th, 2015 1:43 AM

Electric cord damaged.

Battery is completely discharged or battery has failed or power cord not properly inserted into outlet.

Battery or AC Power Adapter not properly inserted into handle of tool.

Battery is too low (green light)

Tool, AC Power Adapter or battery is too cold or too hot

- Bring tool, AC Power Adapter or battery to correct operating range between 15°F (-10°C) to 122°F (50°C) by allowing the tool to sit in a conditioned room. NOTE! Fitting must be repressed if tool stops in the middle of a press cycle. Failure to do so may result in a leaking fitting.

Related Ridgid 100-B Manual Pages

Similar Questions

My KJ 3100 won't start after several attempts it's bin working for a month but trying to start up no...

head to turn

my pipe threader humms when you try to turn it on and won't run the machine. How do I fix ?