Ridgid 1822-I Support Question

Find answers below for this question about Ridgid 1822-I.Need a Ridgid 1822-I manual? We have 1 online manual for this item!

Question posted by Lburchett75 on January 10th, 2023

Oil In Gear Housing

Current Answers

Answer #1: Posted by kane1234567 on January 11th, 2023 3:12 AM

- Leaking oil seal: One of the most common causes of oil in the gear housing is a leaking oil seal. This can happen when the seal is damaged or worn out, allowing oil to escape from the housing. To fix this, the seal will need to be replaced.

- Worn or damaged gears: Another potential cause of oil in the gear housing is worn or damaged gears. This can happen when gears are not lubricated properly, are exposed to high loads, or are made of low-quality materials. To fix this, the gears will need to be replaced or repaired.

- Overfilled oil: Sometimes, too much oil can be added to the gear housing, which can cause oil to spill out. To fix this, the excess oil will need to be drained and the proper amount of oil added back.

- Loose or damaged plug/drain port: The gear housing may have a plug/drain port that is loose or damaged. This will cause oil to leak out. To fix this, the plug/drain port will need to be tightened or replaced.

- Inadequate ventilation or contaminated air filter: Sometimes the gear housing may not be ventilated properly or the air filter may be clogged, this can cause condensation inside the housing and lead to oil leakage. To fix this, the ventilation should be improved or the air filter should be cleaned or replaced.

It's important to address the issue promptly to avoid costly repairs or damage to the equipment. In case of any doubt, please consult an expert mechanic or the manufacturer.

Answer #2: Posted by SonuKumar on January 11th, 2023 9:37 AM

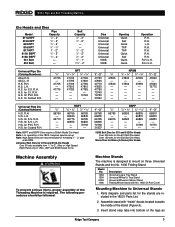

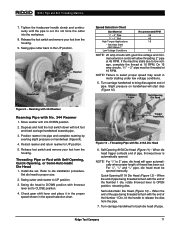

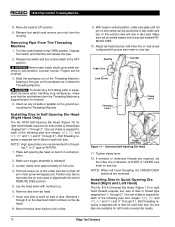

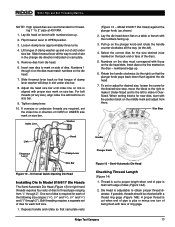

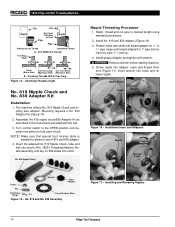

follow - table of content

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Ridgid 1822-I Manual Pages

Similar Questions

I can't fine in the operators manual for my r350che that part that tells me how to adj. the pres. On...

Is Ridgid kollman k-380 snake drain cleaner better than Brasscraft BC 400 in cleaning the outsdide d...

my pipe threader humms when you try to turn it on and won't run the machine. How do I fix ?

I want to change blades on my saw and I can't find my manual.