Poulan P4018WT Support Question

Find answers below for this question about Poulan P4018WT.Need a Poulan P4018WT manual? We have 3 online manuals for this item!

Question posted by Anonymous-168595 on June 22nd, 2021

Piston Compression

Current Answers

Answer #1: Posted by SonuKumar on June 22nd, 2021 7:45 AM

(Good review found in the website above link)

Piston Compression

gasoline engine with the capacity equal to 40 cc.

https://www.manualslib.com/products/Poulan-Pro-P4018wt-322361.html

request to refer to manual for more detailed information

https://www.youtube.com/watch?v=GPrdDKY0Agc

How much compression should a Poulan chainsaw have?

Normal compression readings are between 90 and 110 psi for a two-cycle engine like Poulan saws use.

What should compression be on chainsaw?

around 110 psi

According to Stihl USA, the minimum compression reading for their chainsaws should be around 110 psi. Some individual engines may run a bit higher or lower and the temperature of the tool can affect readings. A cool chainsaw runs low, while a hot engine that's been running for awhile will usually be higher.

https://www.youtube.com/watch?v=GPrdDKY0Agc

How much compression does a 2 stroke need to run?

Minimum 2 Stroke Compression Chart

A 50cc and 65cc 2 stroke dirt bike should have a minimum compression of 120 PSI to run properly. Good compression is about 150 PSI. An 85cc 2 stroke dirt bike should have a minimum compression of 130 PSI to run well. Good compression is 150-160 PSI.

What is good compression for a small engine?

90 pounds per square inch

Most small engines require at least 90 pounds per square inch (PSI) of compression when hot, and 100 PSI when cold. If air is leaking somewhere in the engine, you will notice a drop in compression.

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

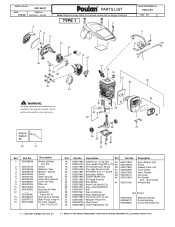

Related Poulan P4018WT Manual Pages

Similar Questions

what is a the part number for a piston and rings for a Pr48bt leaf b

I need to know where the EXTRA wire from the coil going to the kill switch connects. It is the bigge...