Pfaff hobbylock 796 Support Question

Find answers below for this question about Pfaff hobbylock 796.Need a Pfaff hobbylock 796 manual? We have 1 online manual for this item!

Question posted by lindabradyhelton on October 15th, 2014

Needle Change

How do I change a double needle on the pfaff 796? I do not have a "hex" attachment. Do I need to buy one? What is the correct number to buy the needle and do they come double attached or do you install them singular? One at a time?

Current Answers

Related Pfaff hobbylock 796 Manual Pages

Similar Questions

Upper Blade Position

I have replaced the upper blade in the serger hobby lock 796 I can't return the blade to the proper ...

I have replaced the upper blade in the serger hobby lock 796 I can't return the blade to the proper ...

(Posted by debpicco 2 years ago)

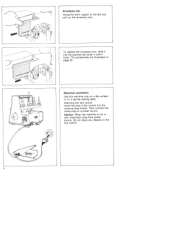

Where Can I Obtain Accessory Kit For Hobbylock 796

how can I obtain an accessory kit or Hobbylock 796

how can I obtain an accessory kit or Hobbylock 796

(Posted by selbyag 3 years ago)

Pfaff 259 Sewing Machine Won't Run With Foot Petal

I have a pfaff 259. When I push on the foot petal the motor runs but the machine itself doesn't run....

I have a pfaff 259. When I push on the foot petal the motor runs but the machine itself doesn't run....

(Posted by Aemazing 8 years ago)

Pfaff 1245 Sewing Machine

How can I change the oil wick on my Pfaff 1245 walking foot industrial sewing machine please?

How can I change the oil wick on my Pfaff 1245 walking foot industrial sewing machine please?

(Posted by janeellenjones 11 years ago)