LiftMaster 8550 Support Question

Find answers below for this question about LiftMaster 8550.Need a LiftMaster 8550 manual? We have 1 online manual for this item!

Question posted by armirshahi on December 25th, 2013

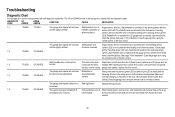

Error 11

What is error 11 means on LiftMaster model: 8550 display?

Current Answers

Related LiftMaster 8550 Manual Pages

Similar Questions

I Have Installed A Chamberlan Garage Door Opener And The Remote I Was Using Is

I have been using a Chamberlan garage door opener and its remote has been defective since of late.Pl...

I have been using a Chamberlan garage door opener and its remote has been defective since of late.Pl...

(Posted by donweera42 8 months ago)

Garage Door Opens After Shutting.

My Lift master 8550 inside keypad is Inside wall pad is model #880LM. outside keypad Model # is 877M...

My Lift master 8550 inside keypad is Inside wall pad is model #880LM. outside keypad Model # is 877M...

(Posted by BONNIECA92 2 years ago)

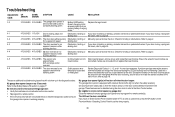

Garage Door Wont Close

garage door starts to come down but then stops and lights flash

garage door starts to come down but then stops and lights flash

(Posted by djsyencer 6 years ago)

Error Code 41 Garage Door Liftmaster 8550 Won't Close

(Posted by jonkrzyc 10 years ago)

Replacing Backup Battery In Garage Door Opener.

How do I replace the backup battery in the LiftMaster 3850 garage door opener? Are there instruction...

How do I replace the backup battery in the LiftMaster 3850 garage door opener? Are there instruction...

(Posted by melindanannin 12 years ago)