Hitachi C8FSE Support Question

Find answers below for this question about Hitachi C8FSE - 8-1/2" Sliding Compound Miter Saw.Need a Hitachi C8FSE manual? We have 1 online manual for this item!

Question posted by urface29367 on January 17th, 2015

Great Website. All Questions. No Answers. Freaking Genius

The person who posted this question about this Hitachi product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Answer #1: Posted by hzplj9 on January 17th, 2015 3:35 PM

As you haven't stated what your problem is I can only give you a link to the User instructions so you can give us more to go on.

http://www.hitachi-koki.com/manual_view_export/pdf/C99169362_C8FSHE_400.pdf

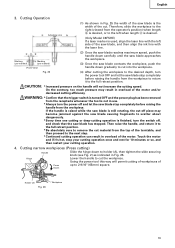

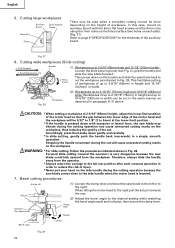

Related Hitachi C8FSE Manual Pages

Similar Questions

Trigger Problems Nr83a2 S

trigger blows out when air is applied

trigger blows out when air is applied

(Posted by bbertrand70663 7 years ago)

Need A Replacement Cord For Cr13vby,having No Luck Locating This Anywhere. Any S

any suggestions where to purchase a replacement cord fro

any suggestions where to purchase a replacement cord fro

(Posted by Rdempster27 7 years ago)

Need Part For Hb-d102/d103 Home Bakery

Need mixing blade for HB-D102/D103 Home Bakery

Need mixing blade for HB-D102/D103 Home Bakery

(Posted by maryannschaffer1 8 years ago)

Clamp Lever

I just got a hitachi c10fce2 compound miter saw. I have not been able to move the saw from its packe...

I just got a hitachi c10fce2 compound miter saw. I have not been able to move the saw from its packe...

(Posted by bigvern 11 years ago)