Hitachi C12LSH Support Question

Find answers below for this question about Hitachi C12LSH - 12" Dual Bevel Sliding Compound Miter Saw.Need a Hitachi C12LSH manual? We have 2 online manuals for this item!

Question posted by dfremault43 on August 23rd, 2015

How Do I Unlock Tv Tv Says Locked

The person who posted this question about this Hitachi product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Answer #1: Posted by techyagent on August 24th, 2015 9:08 AM

- To lock or unlock channels:

- Press the Menu button on your remote control.

- Select Settings.

- Highlight System and press OK/Select.

- Select Parental/Purchase.

- Enter your Parental Controls PIN.

- Select Parental Preferences.

Use Press and hold the DISP button on your remote for 3 secs.

Thanks

Techygirl

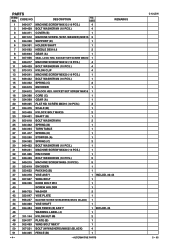

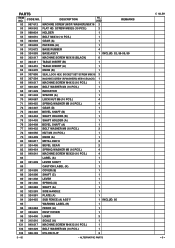

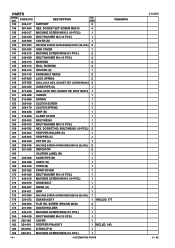

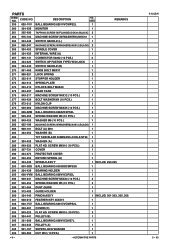

Related Hitachi C12LSH Manual Pages

Similar Questions

That's The Original Hitachi Japonês?

I'm looking for hitachi miter saw 10" japonês original not the metabo you guys have

I'm looking for hitachi miter saw 10" japonês original not the metabo you guys have

(Posted by Pereirafulr 2 years ago)

Wiring Diagram For Hitachi Miter Saw

I bought a switch for Hitachi c10 fc2 & need a wiring diagram to hook it upThank You Dave

I bought a switch for Hitachi c10 fc2 & need a wiring diagram to hook it upThank You Dave

(Posted by delliott49 7 years ago)

How Do I Get My Ps3 To Show A Picture On My Hatachi Tv

(Posted by Anonymous-137302 9 years ago)

Where Can I Get A Free Manual On The Hitachi C12rsh 12' Slide Compound Miter Saw

(Posted by kathy86883 14 years ago)